Engine Management

Comprises the management of engineered activities; fuel delivery, air/pressure, coolant, acutation(exhaust controls), occurrences analysis/recording/reporting(gages)

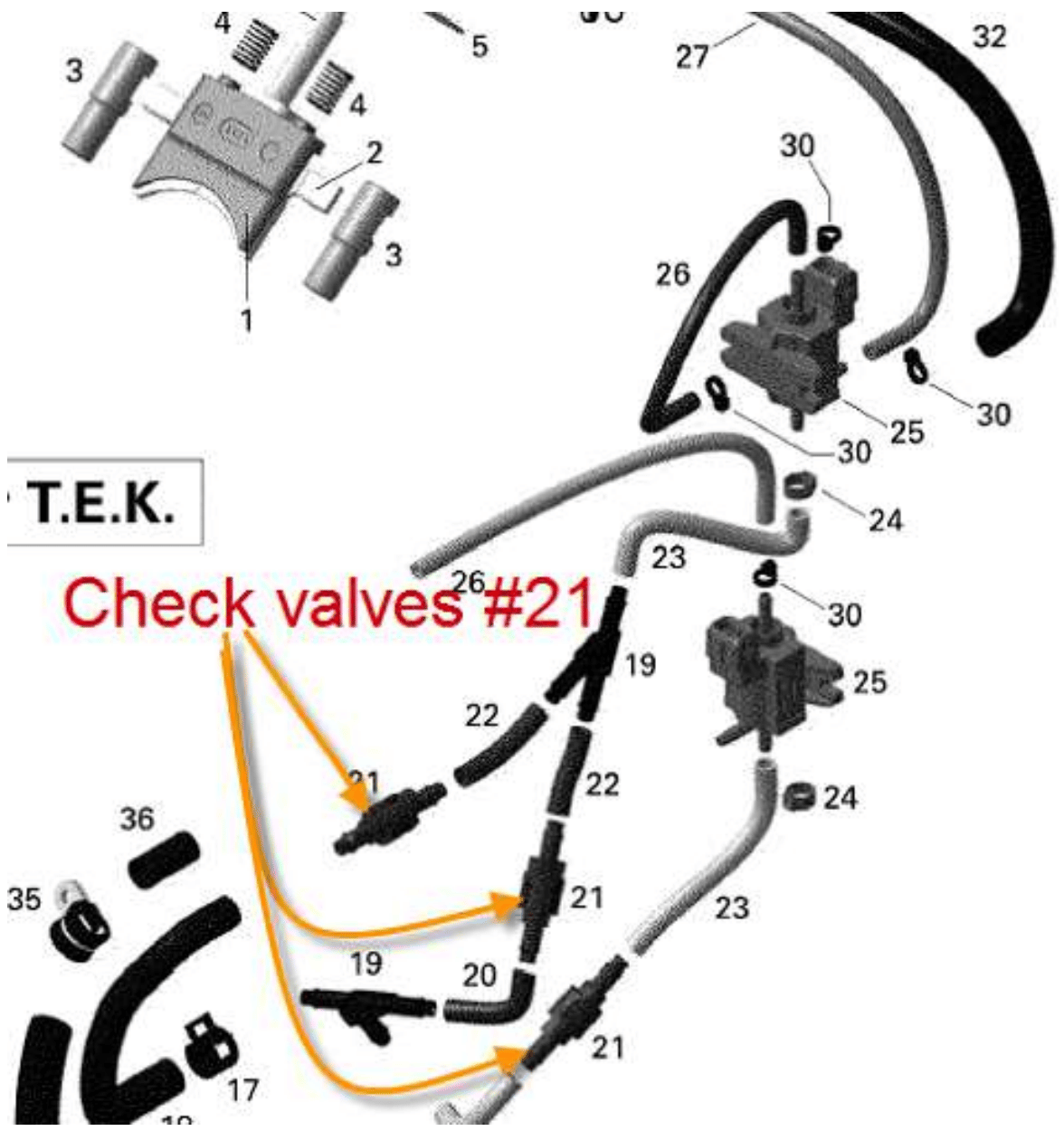

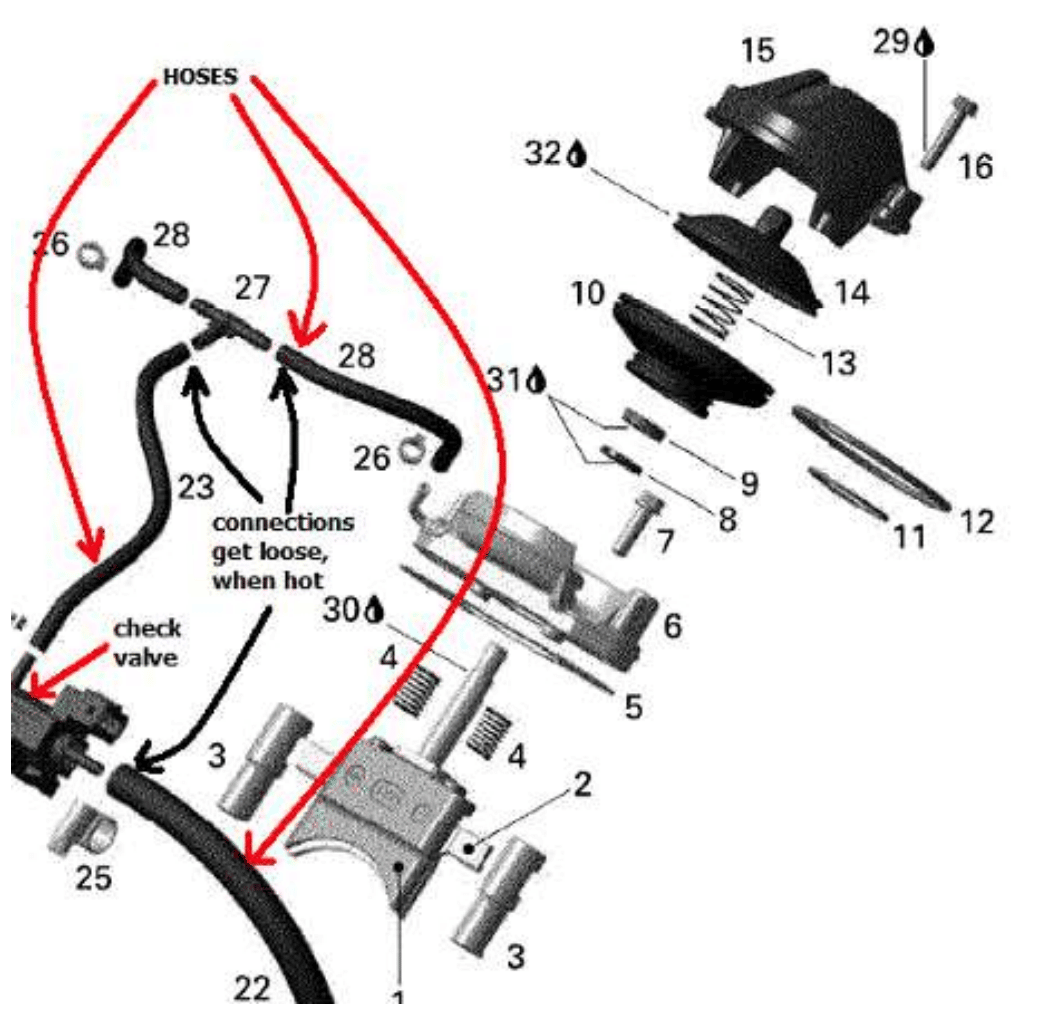

Rave Check Valves

Events – (Engine will reach maximum rpm only for a moment) The sled would pull well for 2-3 seconds, then rpms start drifting low forcing you to turn out.

1)Ensure that all rave check valves are phased in the proper direction.

2)Check valve leak test – Install test pump and pressure to 5psi. Valve should stand pressure. Install pump opposite side, pump, air should flow freely.

800 PTEC engine

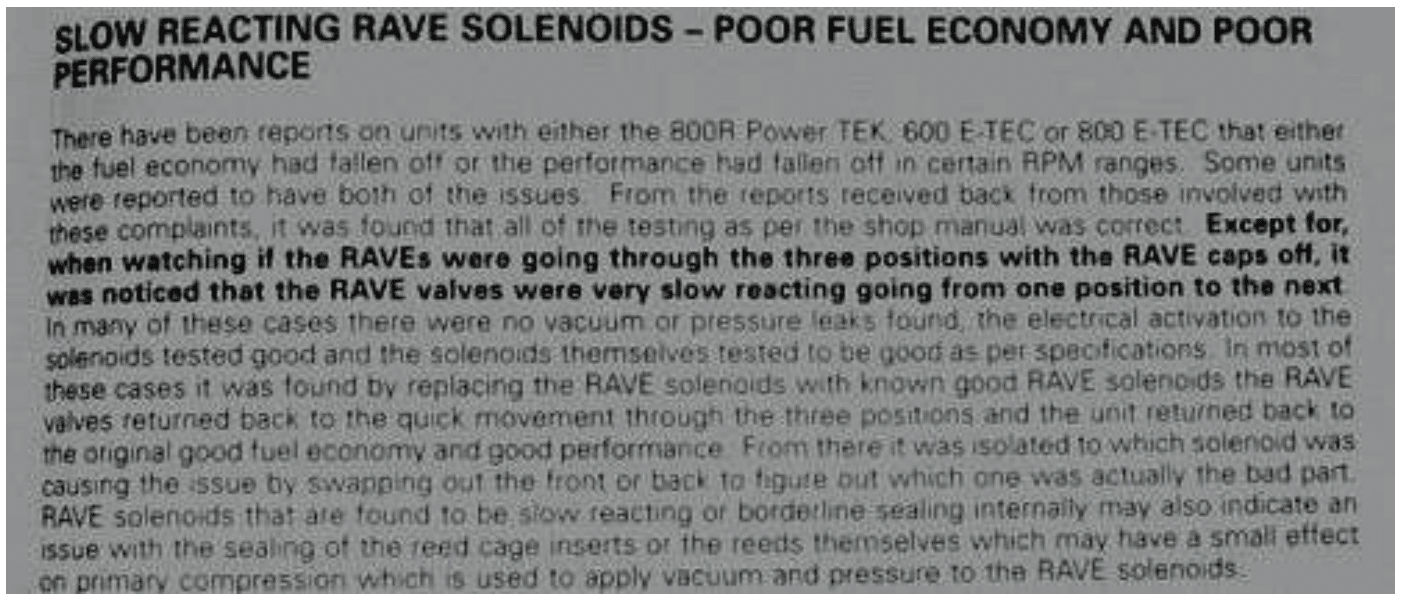

RAVE Performance

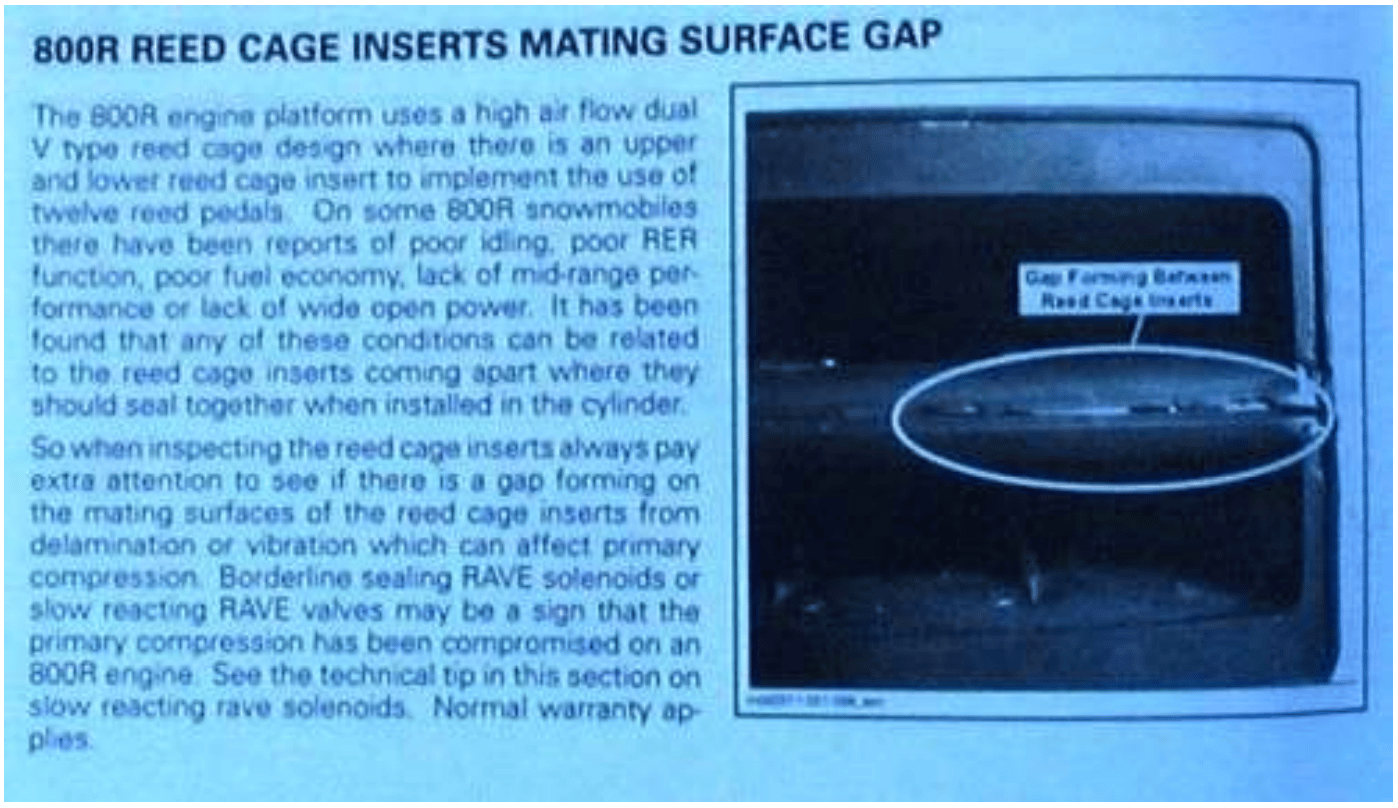

800R Reed Cage Inserts Mating Surface Gap (ties in wtih [slow reacting rave solenoids])

800R Engine Detonation Level Detected – Too high – Code P-1326

Ski-Doo has made available to their dealer network a new software update for their 2009 Ski-Doo models fitted with the 800R engine package. Some units would go into a permanent limp-home mode (engine detonation level detected too high) that required a dealer to reset the mode.

If this should occur,(Code P-1326) an authorized Ski-Doo dealer can upload the new calibration into your machine.

This calibration will still protect the engine from detonation and if needed it will limit the engine to limp home. This new calibration allows the user to reset the limp-home by simply shutting the unit off and restart-it, instead of having to take it into the dealer to be reset with BUDS.

Crankshaft & Crankcase

800R known for bad crankshaft wobble that contributes to excessive clutch wear and short belt life. Get the clutch off the engine.

Get a dial indicator on the end of the crankshaft stub to check for crank end excessive runout. Crank taper may be out of spec and this will certainly cause excessive premature wear of new clutch components.

Put dial indicator 1/8 inch in from end of crank stub.

Maximum deflection PTO side is 0.06mm (.0024) engine type = ALL

I have had a customer who warantee a crank on an 08 and it took 4 crankshafts from BRP before a spec crank showed up – crank came in, checked runout,(.003+) sent it back Nuther crank come in, again (.003+) sent it back, nuther crank come in (.0025) sent it back. 4th crank come in and (.002) The 4th crank came with less than out of spec runout.

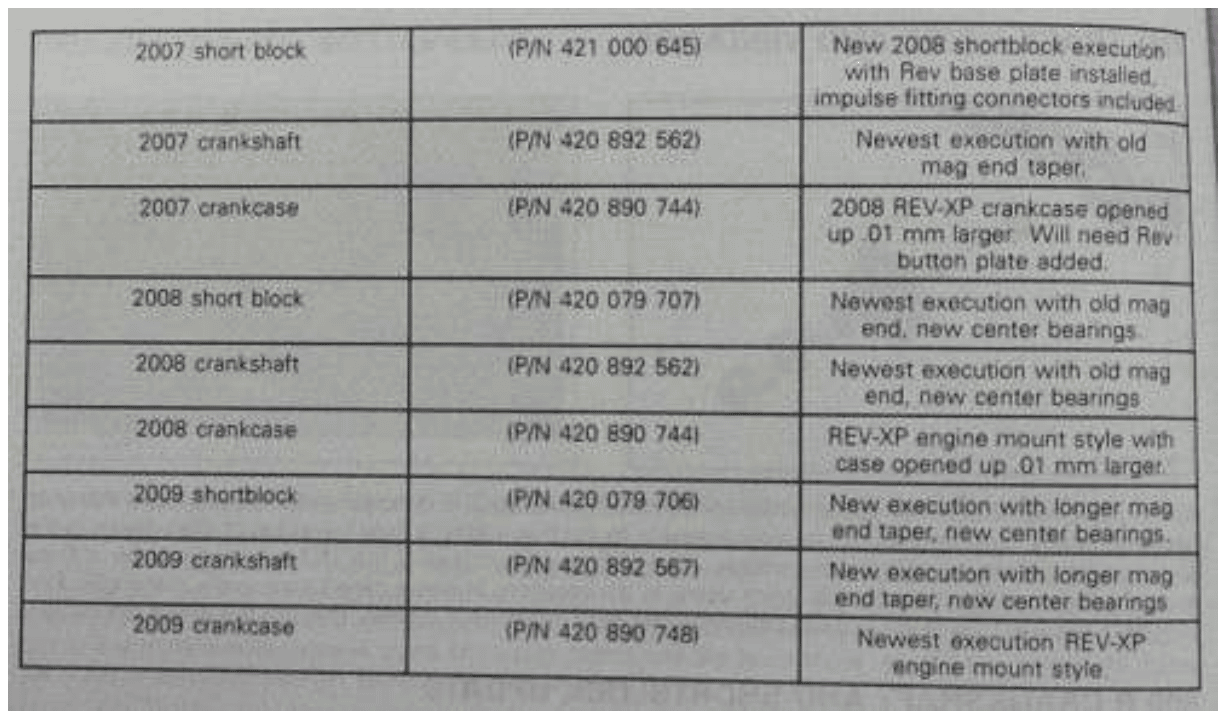

2007 crankshaft #420892562 – Newest crank with old mag end taper

2008 crankshaft #420892562 – Newest crank with old mag end, new center bearings

2009 crankshaft #420892567 – Newest crank with longer mag end taper, new center bearings.

A- Contaminated Carburetors No. 2008-12

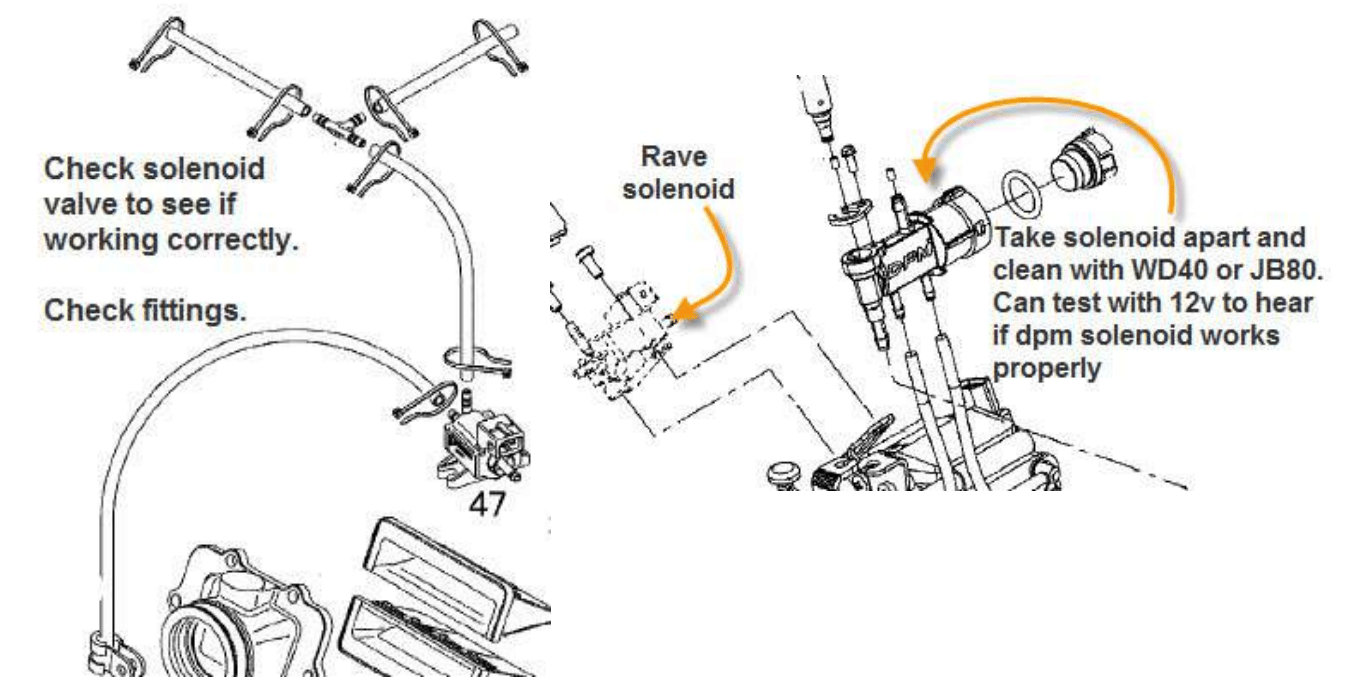

B- Kinked DPM Vent Hose

C-Corroded DPM solenoids 2009 model

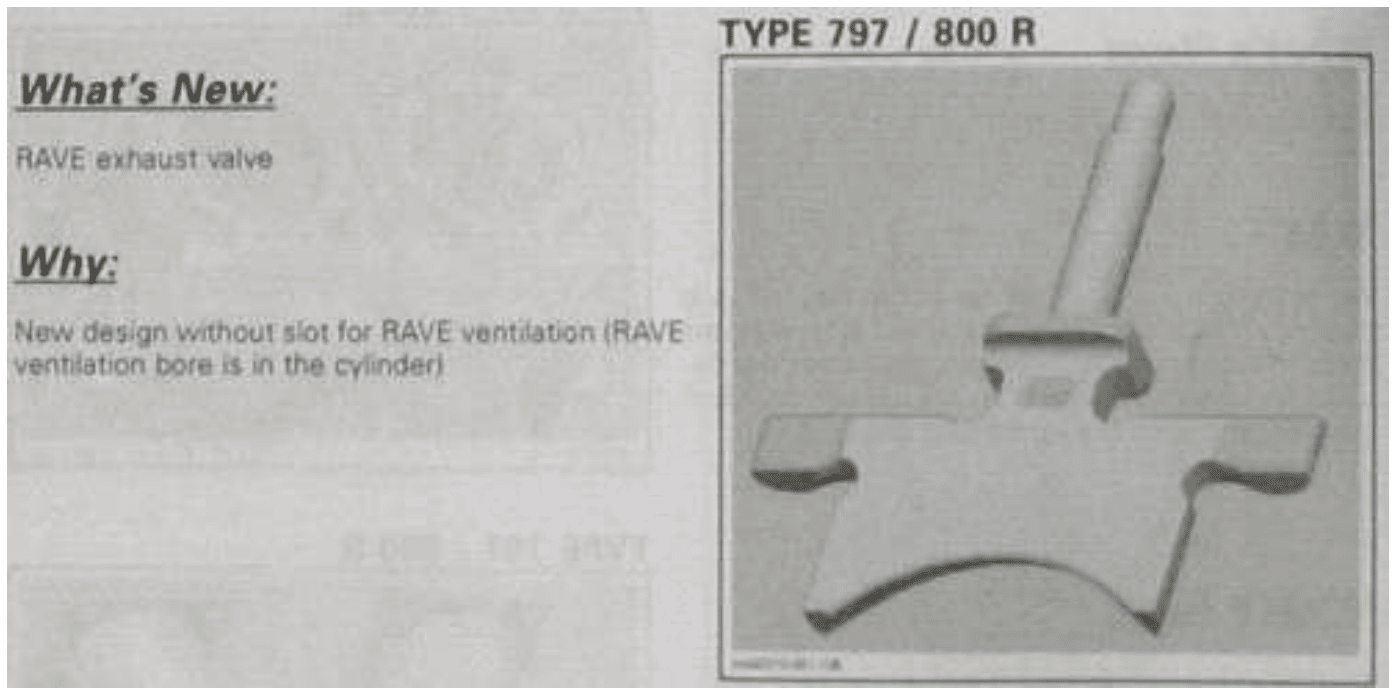

D- 800R rave valves. 2010 update

E- 2009 800R Crankshaft and Shortblock update.

2 major changes. 2009 magneto end taper is longer and will only work with 2009 flyweeel. Second change is center main bearings are grease filled with integrated seals. Different big end bearings, polished connecting rods

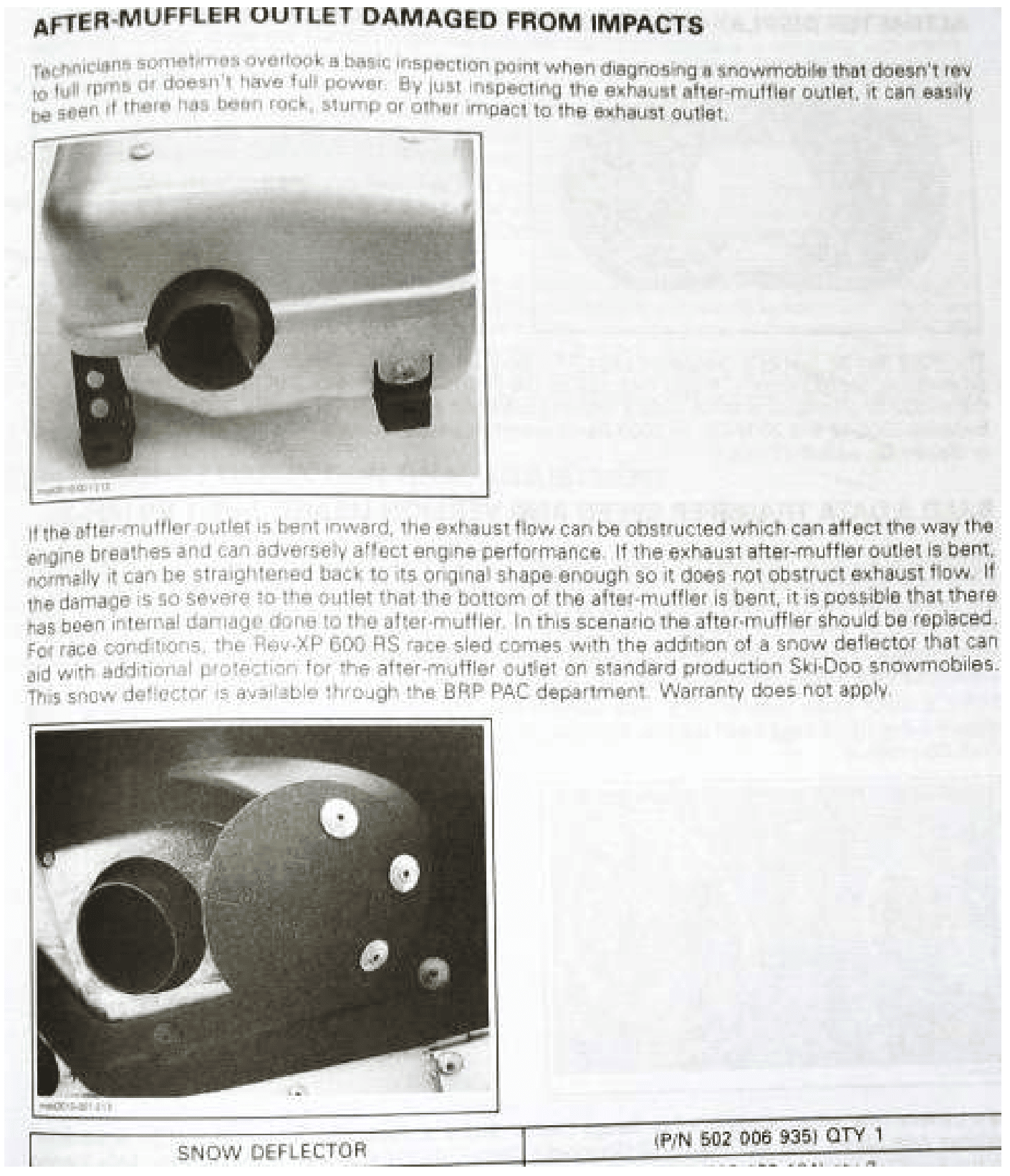

After-Muffler Outlet Damage from Impacts

Don’t overlook a basic inspection point when diagnosing the engine having low rpms when full throttle or engine does not have full power. Inspect exhaust after muffler outlet and confirm there is no damage to the roundness of outlet.

If outlet is obstructed by dent, then straighten and look inside to inspect for internal damage to the inner wall to further see if deeper obstruction. Additional snow deflector BRP#502006935

Note E-10 fuel should not be equated with E-85 which contains 85% ethonol. If E-85 is used it will cause engine starting difficulties and engine power fluctuations and even engine damage.

E-10 fuel = 10% ethonol, the BRP engine is designed to run with, use the highest octane available.

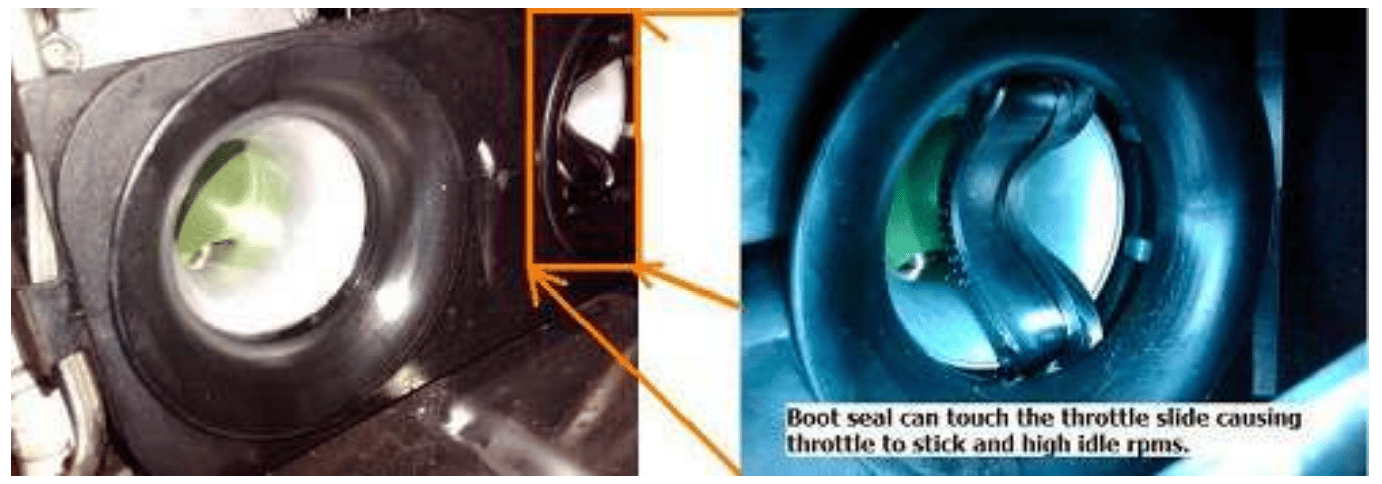

Throttle sticking (possible causes)

Deformed Air Intake Adapter – Boot seal can touch the throttle slide causing throttle to stick and have high idle rpms. (well known to happen on 09/10 models)

Throttle Cable Adjustment

If you have changed your handlebar riser, confirm that the throttle cable is adjusted properly. I have had customers who run the 09xp clutch kit and could not get correct rpms at all even after emptying the flyweight pins. After much grief looking all over the sled at engine management and such, ended up taking the airbox off and running the throttle full open – notice that the throttle slides only going to about 3/4 open.

Have had 2 customers end up with this result so hope it is one of the details you check after you do a mod.