Question) Hi Joe, I have a MX-Z Adr/2006 800 p-tek button secondary w/1.25 track. I took my secondary apart last night and noticed that I’m running a stock green spring, at that time I opted to stay with the stock green 180/300. What would the performance difference be in my sled with any other spring?

Answer) The secondary spring start force influences “engine speed acceleration”. The time in seconds (10ths) for the engine to speed up from one rpm to a higher rpm.

Going from a 160 to a 180 to a 200 to a 225, each spring force will allow the engine to speed up rpms quicker. If you pull off in deep snow, making a run with each spring you’ll notice as you cycle the throttle at an example 30mph track speed; each higher start force, the engine will “recover rpms” quicker.

Ideally at top end mph, the spring forces are nearly the same and should produce similar top speed as long as the rpms are the same.

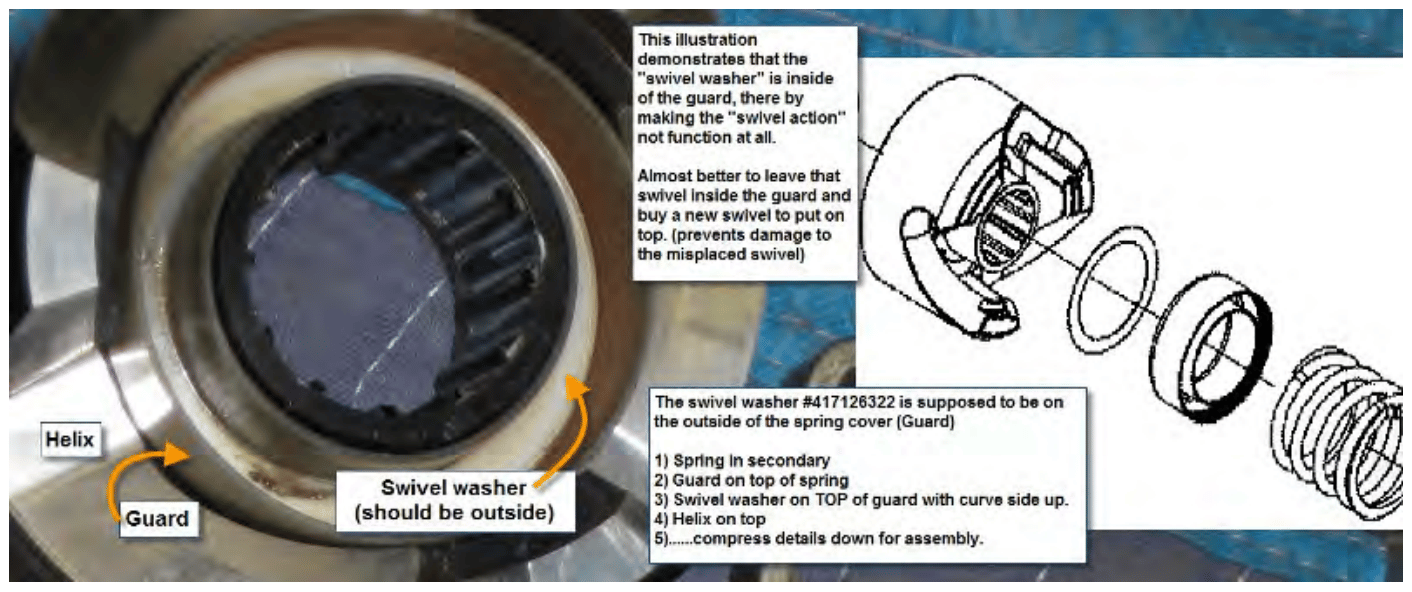

The most important detail to make your “REV” secondary work correctly is to have the white spring cover over the spring and the white swivel washer placed correctly “in between” the spring cover and the helix. The swivel washer cannot be put inside the spring cover. If the swivel washer was put inside the spring cover – just leave it installed and go buy a new swivel washer instead of damaging it trying to extract it.

Springs – Economical improvement with secondary spring

I get this question of doing economical improvements to the clutches on a stock sled.

Here is an example of gaining efficiency with paying attention to the heat your clutches can produce from belt slip. How to lower the clutch temperatures and increase performance. There is a point a tuner can go too far in a certain “tuning window” with spring forces. Another problem can surface – Excessive rpms, but remember, flyweight settles rpms, so this leaves you to change flyweight grams.

Never look at it as problems, rather an opportunity to gain something.

Take notes, they’ll be your guide for the pursuit of a “best system”.

—– Original Message —–

From: Inquisitive tuner

Date: Today

Subject: Via the iBackshift.com website

I have a stock 800. Just wondering if there is anything that can be done to increase performance by just working with the stock clutch. Are there any way(s) to add just a part or parts “that” will help from the holeshot through mid-range. Not really worried about top end mph.

Thank you,

I. Quisitivetuner

—————————-

Joe writes:

Hello: Here is an academic discussion on secondary springs and the capacity they hold , offering better efficiency in a clutch.

If you run your sled, you should take note of how your secondary runs for heat.

You go for a run in a predetermined course. At the finish you grab the brake quickly and stop the sled, Pop hood feel temps of clutches.

Heat = belt slip. How can you recover hp and reduce heat to put it to the ground? Helix? Secondary spring?

To quickly learn what a spring can do for you to reduce heat…Look at the facts.

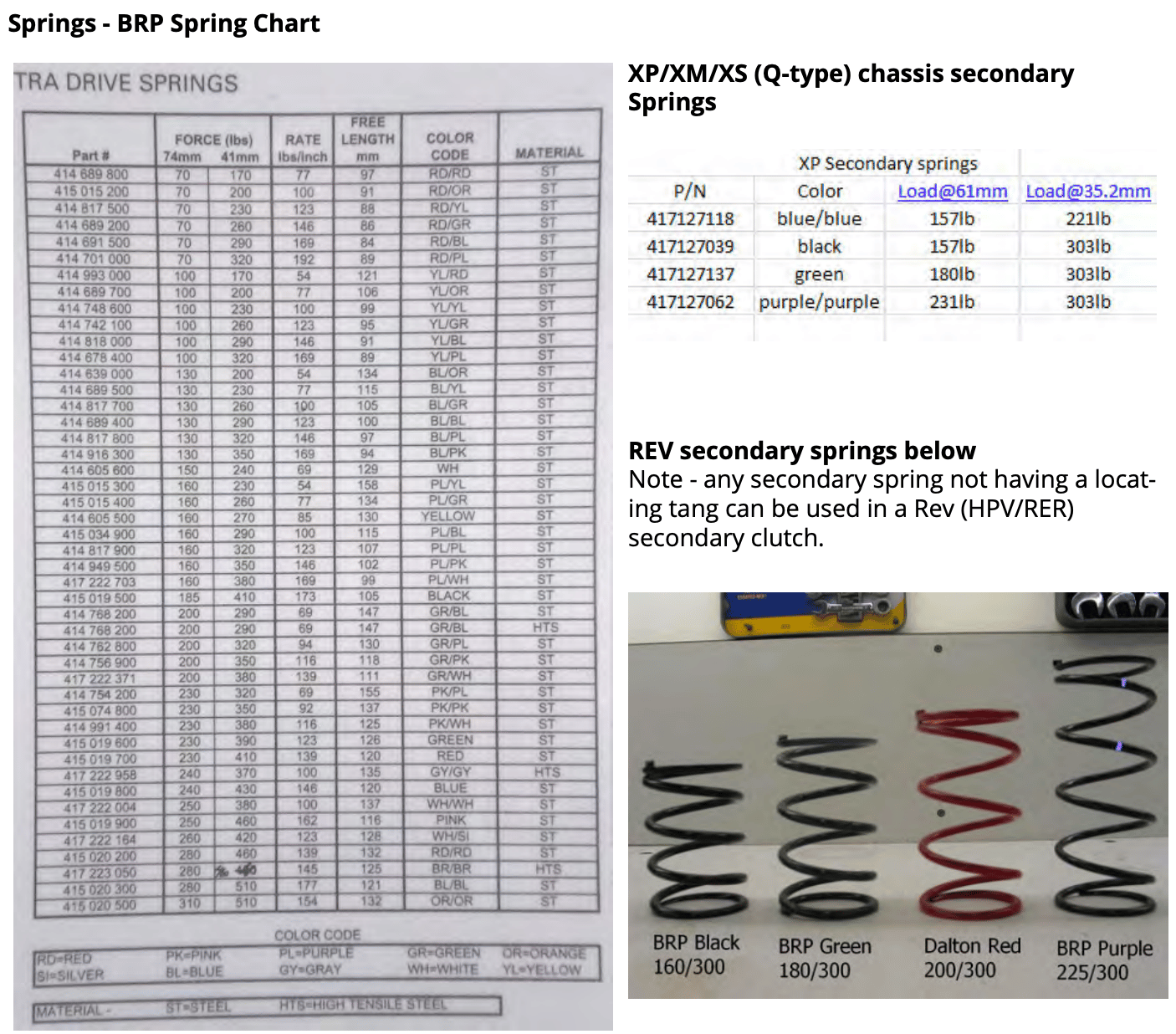

Your stock 800 spring = Green 180/300

Options

Dalton red = 200/303

Dalton red/yellow = 218/305

Purple Doo = 225/303 or XP 231/303

Since you mention you do not care about top end; All these springs have finish force of 300 lbs. so the top end ideally should reveal same performance in mph.

Look at spring forces in bottom end of shift 180/xxx, 200/xxx, 220/xxx and neglect the finish forces. What would going to any of these springs help? Each one will offer increased belt clamp force than the former. The sheaves will push harder in the lower ratios than previous spring.

The temperatures revealed will be lower on the same test run with each increase of spring. There may be another benefit to this change; increased acceleration if the rpms stay the same or if the rpms are now correct – At top end mph, the engine speed should stay about the same because of the xxx/300lbs finish with all the springs.

The choices made should pep up your bottom end and midrange acceleration.

Springs – Effect of primary spring final force

Buddy writes) Hi Joe,

We have a clutching deficiency. Our 800 using this new track, we are running 2 grams lighter than our older track. The new track hooks up a lot better coming out of the gate, but sacrificing top end.

Last year at the hill climbs, we’d get the hole shot and then about 300-400 feet out a few of the competitors reel us in. The backshift went poor and peak rpms went a little low after the new track. I started removing weight until it would rpm correctly and backshift improved.

Then we were still quickest to the second hump in the hill. Removing the 2 grams slowed the top end speed because of over revving. There is room for improvement on top end. Our competitors have closed the gap.

In 20XX we ran the same set up with the old track except the pin weight was two grams heavier (22.7) and it had great back shifting and top end speed. We changed the track because it has more out-front hole shot.

For clarification: the new track hooks up much better than the older track. Every time he’s back on full throttle the sled pulls hard enough the backshift is good, but because i lightened the clutch weight, now the engine starts to overrev after 400 feet.

Here is the complete set up that over revs on top end. It will not back shift if we add even 0.5 grams.

XXX Ramps @ clicker #4

200/320 primary spring

19.4 Grams

XX/YY Helix

Purple secondary spring

21/49 gearing

391 Belt

…end.

Joe writes) Hey Buddy.

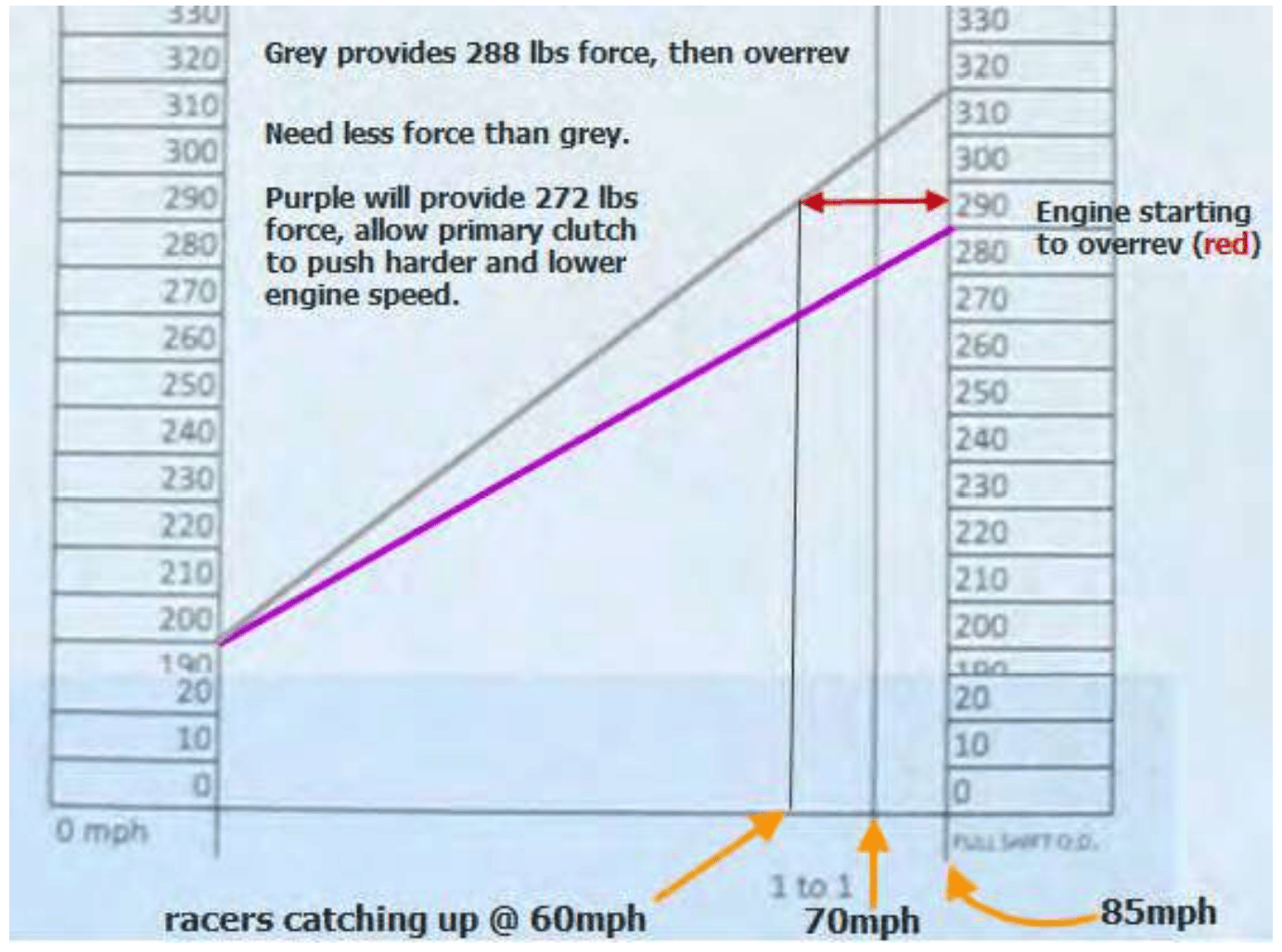

Problem with over revving at 400 to 500 feet.

If add even ½ a gram the backshift goes poor but engine speed is correct at 400~500 feet.

Since the problem is at ¾ shift to full shift, let’s look at what you can change on the parts settings.

Primary spring end force

Ramp angle (from 2/3 of the ramp to the end of it)

Secondary spring final force

Helix – finish angle

Aaen Pg 76 in his book says.

Need less RPM on top end, then less finish force on primary spring. More aggressive ramp curve. Less secondary spring final force. Larger helix angle.

The easiest part setting available to change is the primary clutch spring end force. There are no secondary springs with a lower final force. The ramp you have would need grinding. You are not into making a new helix reshaped to compensate for the engine speed increase.

Primary spring 200/320. You can simply go to a 200/290. Take the primary spring end force and lower it. Leave the start force alone and only change the setting in the shift ratio where you are having the problem.

A rule of thumb is, estimated 20 lbs drop in final force will lower engine speed by 150~200. If it does not noticeably lower engine speed the clutch will still push harder and acceleration will be hard.

Go from a 200/320 to a 200/290 and test it out.

Springs – Effect of secondary spring final force

Question) Hi Joe. I do 30-40% off trail, breaking fresh snow and working at finding more places to do more off-trail and power lines. I want to increase my percentage off trail and fix my rpms on trail.

WOT pulls in snow are regular and hold WOT until planing on the snow and find that spot where the sled likes to ride on plane.

I do carving and blip throttle like anyone else as needed. I don’t want to touch the way the sled runs from bottom to midrange in the snow.

Vehicle Data

8000 rpms

XXX ramps

160-290 primary spring

XX/XX helix

231/303 purple skidoo secondary spring

22 grams, clicker 3

23:45 gears

1.5 track.

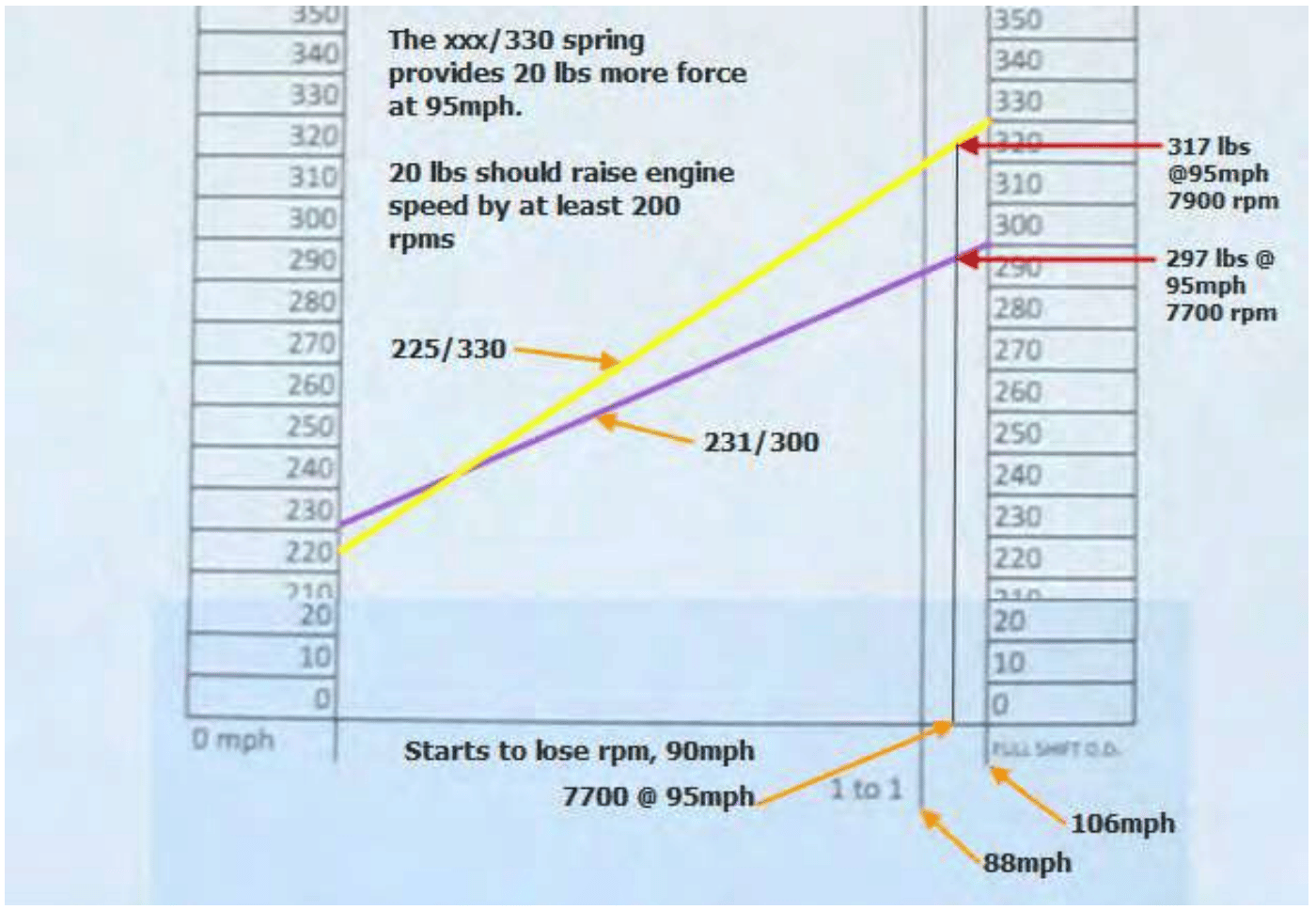

My problem; to get to-and-from breaking fresh snow, I’m on the trail. Sometimes when I get to go past 90 mph my engine starts to lose rpms. If I keep holding it past 90 the rpms will go down 300 and doesn’t pull. At 90mph, on and off the throttle, backshift is poor.

Answer) There are some easy changes to make.

Aaen’s book (Ed. 2007, pg 13) says, if you want to improve efficiency or backshifting, adjust the driven clutch. (Secondary clutch)

Aaen’s book (Ed. 2007, pg 76) says, when losing engine speed towards top end you can change these parts.

Add more primary spring end force. Less final angle on the TRA ramp (less aggressive). Lower helix angle at the finish (less final angle). Add more secondary spring final force.

About 88mph is where the push force of the primary clutch is overcoming the resisting force of the secondary clutch. Combined helix angles and spring forces at 95mph does not have enough resistance to allow the engine speed to uphold a straight shift of 8000 rpms.

Aaen Spring rule: The stiffer the spring, the higher the side force.

Rule of thumb: for every added 10~12 lb spring force, the engine speed should raise 100.

Adding secondary spring final force will make a higher rpm. Adding secondary spring final force will lessen engine speed loss at that high vehicle speed. The higher end force will quicken the backshift.

Going from a 231/303 to a 225/330 will raise the spring force by 20 lbs at 95mph. Apply that fact to the rule of thumb and the engine should not lose 300 rpms at 95mph

Change the secondary spring.