Belt – 800 belt on a 600/500SS – Don’t do it.

Question) I hear about putting an 800 belt on my 500SS, will it last longer?

Answer) Don’t put an 800 belt on a 600 clutch. An 800 primary has a forged sheave. The 600/500SS is a cast sheave. The 800 belt is a harder compound belt and is designed to run on a forged sheave. The non-800 belt is softer compound and designed for cast sheaves.

What happens is the 800 belt will eventually wear a groove into the sheave at the “shift range” that you normally drive at, literally putting a dished groove on the cast sheaves. Some racers use an 800 belt on a cast sheave because it allows the engine to accelerate quicker from engagement rpms to peak rpm. I would not advise that kind of blend on a consumer sled.

Belt – Deflection adjusted highest and belt still low

Question)One other issue I have is that the belt height adjustment in the RER secondary is maxed out even with a new belt and it is still slightly low. Is there a fix for this?

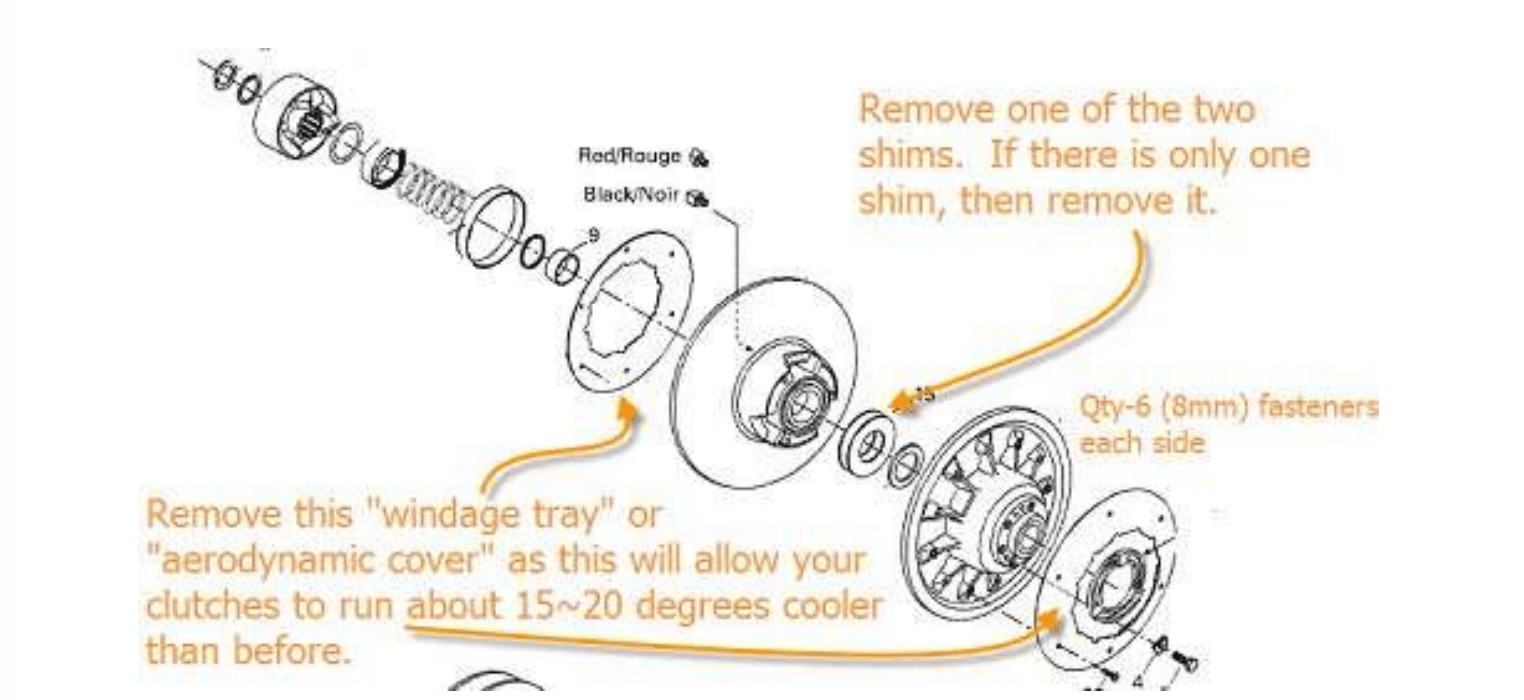

Answer)Yes there is a fix, rather an adjustment. Open up the secondary, there are 2 shims inside of it and can remove one shim then re-assemble and re-calibrate the belt deflection.

Belt – Gap between belt and primary sheaves?

Question) How much of a gap should there be between the Primary halves and the belt? this is sitting without the engine running with the belt pushed to one side, how much of a distance should there be between the edge of belt and the primary sheave?

Answer) With a new belt on at 1.48 inches, anywhere from .020 I have seen up to .080 inches. I believe .050 with a new belt is about average (my experiences)

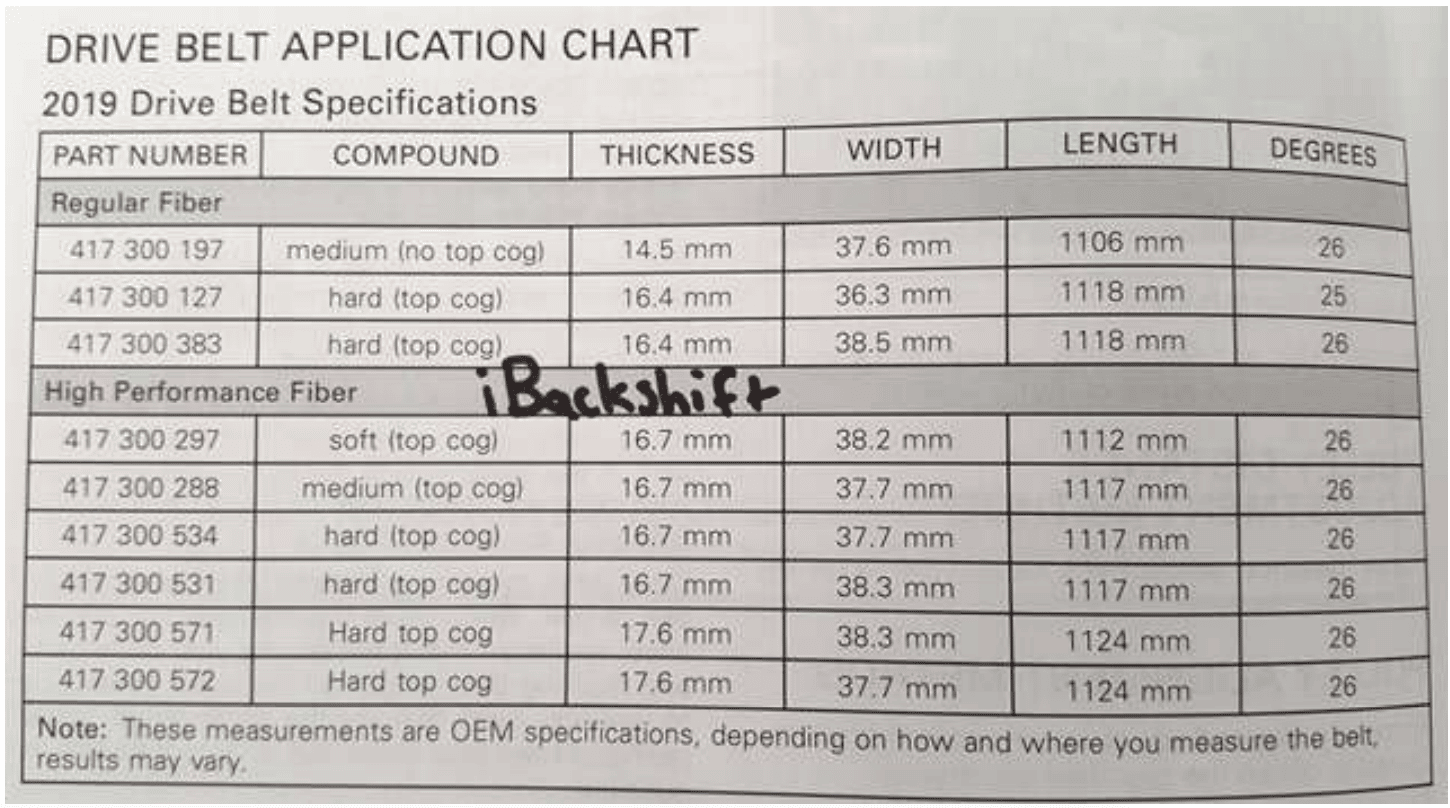

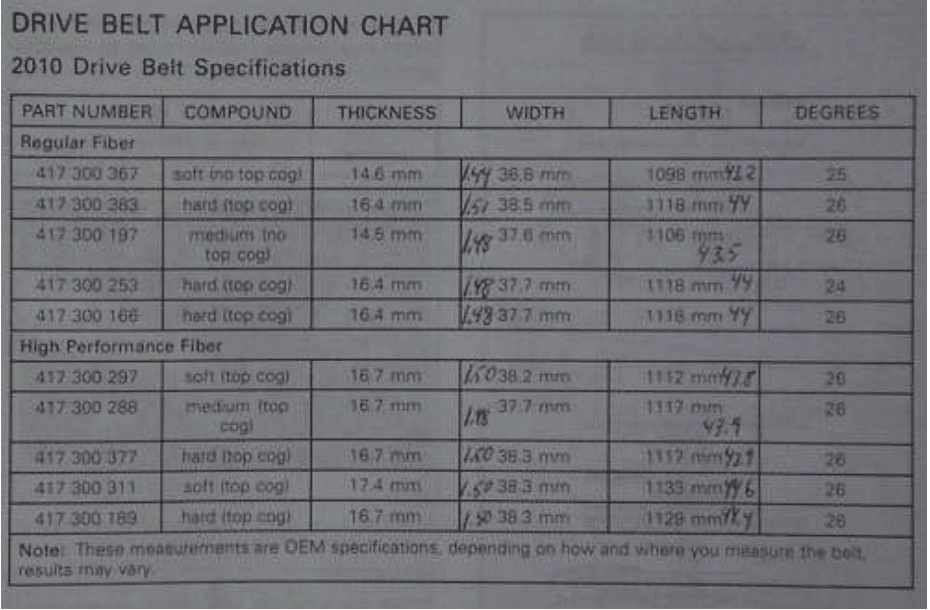

Belt – Application chart – Dimensions and Part Numbers

-Belts can vary in length 1/4″ -+ from spec. Years ago I measured an 8607 that was 5/8 inch longer than spec.

-Owners can choose belts with different lengths – refer to the Skidoo belt application chart above.

The video I linked what I set mine like or any other sled up for good all around deflection. What you are doing by setting this kind of deflection is eliminating a calibration problem that can come from the varying belt length. You are making sure that the right tension is going to be measured regardless of belt length or width.

The sled is with the track off the ground. Engine idling if the track can turn slowly or the track jerks a little bit, trying to turn, or does not turn however you can grab a track lug with your index finger thus pulling the track around – all while the engine is idling.

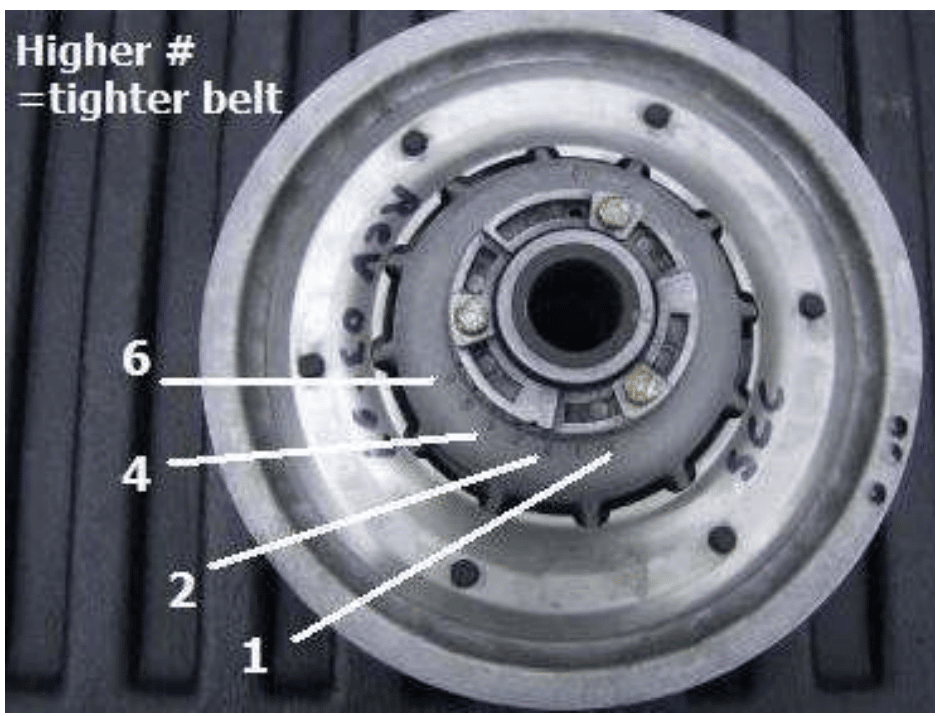

On the mxz/rev chassis with HPV secondary (RER) as the cam number increase, the belt tension will get tighter.

With this kind of deflection in the video linked below I never let my engine idle too long. There are 4~5 cogs wrapped around the stub of the primary and the temperature gets high localized in that area. Excessive idling contributes to why belts will blow about 4~5 cogs off and you hear that “puk puk puk” just before the belt incinerates.

The temperature in that localized area will change the composition of the rubber making it a harder material; eventually separation will happen….BoOm!

Deflection cam at #6, belt still low

IF the belt defleciton cam is on #6 and are not able to get the belt to ride up in the secondary, THEN you can 1)remove one shim from inside the secondary. 2)Reset the belt deflection cam back to #1 position. 3)Peform belt deflection procedure again.

391 Discontinued – 571 now available for 800 and 850

The 417300391 is discontinued Nov 2017. 417300571 is the latest belt from BRP for 800s and 850s. This is one of the most hardened belts Ive experienced, right up there with a Yamaha long track drive belt. In the past with 391s and earlier belts, you could watch the green color on the side of the belt fade to a darker color of brown when getting to the belt high temperature limit. When the green color of the belt turned black, you overheated the belt with temperatures over 220 deg F.

The 571 is different from the previous belts. Older than 2017 belts, the color on the sidewall acted like a liquid crystal thermometer; you know the one that sticks to the glass of an aquarium to tell the temperature.

The belts had the means to tell the temperature by color;

-Green up to 180~190 degrees.

-Brown 190 to 210 degrees.

-Black, belt is running higher than 210 degrees – the sidewall would show a black burned color.

…but not with the 571 belt.

Now the 571, Ive recorded steady temperatures of 290 to 305 degrees in running hard conditions. I have a test guy setting the record of 330 degrees. All my test guys watching the color on the sidewall of the 571 belt and its still a green color after 290 degrees.

Ive blown 531 belts and they blew with no warning; BAM – the top layer peels right off them. I had one blow into little chunks and a ball of yarn wrapped around the clutches. The failure of the 531 is similar to blowing a race belt where the rubber blows off in little chunks, making you cut (Snipping) the aramid fibers off from around the clutches.

The 417300571 belt is the most tough belt i’ve ever tested. I ran it hard enough to make it smell from overheating, to the point of my buddy track poaching behind me could smell the belt from my sled. I have had that belt over 305 degrees and the sidewall stayed the same green color, a little dark for green, but green none-the-less. For me and how I beat my sled, the 571 has been the most tough i’ve ever run.

Belts we tested – “toughness” durability

If you are tempted to run an aftermarket belt, we tested belts and two stand out.

800 & 850 Summits

Gates 49C4266. Seems to be as tough as the 531 but much cheaper price. The belt still blows like a 531 or you can say the 531 blows like a 49C belt. Under the hood when on/off throttle; the wresting and twisting of the engine and driveshaft with lower geared, long track sleds; the engine moves around violently, thrusting out of parallel, the belt cain’t take that shit anymore – eventually peeling the top layer off the belt.

800 & 850 Trail sleds

Carlisle XS821. Seems to be more tough than the 531. The XS821 is a soft belt as you will see by an engine speed drop of at least 100 rpms on a direct change from a 531. With the taller gearing of a trail sled, the engine does not move with a sharp surging action, cycling back and forth in the e-module like a long track does. Its just my quess the softer belt has the means of it being “tough” to withstand the long-legs, slower torque rise of a high speed trail sled.

Many tuners have sent me blown G4 belt pictures with stock clutching and/or modified clutching and 2 common denominator is seen; a top layer chunk/section (tension section) peeled off the belt, or, blowing into little chunks the size of the top cogs.

Aftermarket vs. OEM belts – regarding rpms at full throttle .

The rubber compounds of aftermarket belts are generally softer than the original BRP drive belt. IF you were running the BRP belt and observed your rated rpm (example 8000) and THEN change to an example Carlisle XS803 belt, [reset the belt deflection if required or if you can] and go out and run the sled full throttle. You will observe 7800 rpms at full throttle. The softer compound works harder against the sheave thus causing lower rpms.

What do you do about the 200 rpms loss. 1)change flyweight, or 2)increase clicker number.

Full throttle looking for about 8000 on the tachometer.

Observed 200 rpm lower (7800) at full throttle

Theory

1g = approximate 200 rpms difference.

Need more rpms = reduce pinweight

Need less rpms = add pinweight.

Example: If you needed 8000 and have 23.5g pins installed.

You run and reveal 7700.

8100 – 7700 = 400 rpms. 1g = 200 rpm change.

23.5g – 2g = 21.5g

And go out and do a full throttle run again.

Theory

1 clicker number = approximate 200 rpms difference.

Need more rpms = raise clicker

Need less rpms = lower clicker

Example; if you needed 8000 and observed 7800 while in clicker 3

Then change to clicker 4 and go retest at full throttle.

For mountain and backcountry riders who want the belt to grab hard in the trees and lug the engine to prevent the track from trenching, then can go to a softer drive belt whether it be a BRP or Aftermarket. The softer belt will reveal a more “Squishy” throttle feel, when crawling through the trees. This commentary has been gathered from many tuners.

Belt – Blowing and both clutches hot

Question) I went out today with the stock pipe on my So-n-So-Summit. 14.5g, bang on 7900/8000, clicker 3, track speed 42mph at full throttle, 20:49 gear, new Peak 2.5 track. Had an issue. Belt blew, both clutches were extremely hot. Belt was 1.43″ wide at the top, set it per defection video.

Wondering if I should drop from 20t to 19t in order to compensate for the Peak 2.5 track. Power felt good today and if i didn’t blow the belt i would have had a great day. I worry if i can’t get the heat down on the clutches i am just going to be blowing belts all year.

Answer) Belts blow due to; 1) misalignment, 2) clutch bushing fitness(out of parallel sheaves), 3) incorrect flyweight/clicker calibration (fluctuating rpms) and 3) time in seconds spent at full throttle (overheating)

Check the engine mounts? Are they hard, broken, loose? XP’s double check the E-Module under the primary (pto side) for cracks, and the front pto mount for cracks. Check the clutch alignment.

What are the 2 primary clutch bushings and secondary sliding sheave bushing like for size and fitness?

What belt deflection is being used is it correct? (you noted great deflection)

If bushings are great, flyweight reveals 7900~8000 (correct rated rpms) and 70 seconds or less at full throttle, then ideally the belt should not blow unless misalignment is causing overheating. Misalignment is something you have to check yourself. As each year has rolled along since 08, BRP has kept coming up with new alignment specs. My 2008 sled was one of the worst alignment problems I ever seen, I had to use the additional shims that the doodoctor recommended to straighten my belt out.

If you keep an eye on the temperatures and the engine mounts are good, frame under engine is not cracked…then that belt could last a whole riding season. If you still have problem with belts after checking these details then look into modifying the pto side panels to promote more underhood air exchange; vents and/or a powered blow hole – whatever you can do (but dont modify the belt guard) to exchange hot air.

Keep the left footwell (stirrup) clean of snow. On left turns the left footwell clogs up with snow and it must be kept clean. The latest BRP belt guards are totally enclosed, acting like a conduit to move air more rapidly.

heat is caused by….

Too high of engagement speed and running slow track speeds cycling in/out of engagement

Running the clutch just past engagement speed for a long period of time

Overrevving

Under revving

Engine moving out of alignment and belt scrubbing.

Footwell plugged up with snow so air cannot conduit out to atmosphere from underneath the hood. Not giving the clutches a break by running hard non stop, accumulating temperature when – the first 6 points are working against the rider.

Billy) what are you doing Mike? Did you blow a belt, something wrong, something broken?

Mike) Nothing wrong. My buddy Joe said whenever you can give the belt a cooling break, then give the belt a break. So if you’re having lunch or something to drink, it takes 30 seconds to open up the side panel and let some cold air in and let some heat out. We’re standing around talking for a while anyway – why wouldn’t you give the belt a break?

Billy) Well that is a good idea

Belt Tempurature & Gearing: We have been testing lower gearing since Jan 2009 with the 49 and 51 gears. Now with the G4 chaincase, I have been running 19-53 gears in my 154 x 3.0 sled and God knows I love it.

We know that any lower gearing gives track speed staying power and enhances resistance to load changes while at full throttle. Gearing lower allows the drive belt to move across more of the sheave face surface helping the aluminum extract away more heat from the belt. The belt spends less time in a certain position as the load changes while at full throttle. BRP knee jerk reaction for years for customers on warranty belt issues has been to lower the gear ratio and look what they have done in 2012. 146@ 21:49, 154@19:49, 163@19:51 and to me personally I have tested those gears in earlier models in 154/163’s and there ain’t anything wrong with them – my clutch kits work excellent with the lower gearing that what people are normally pre-programmed to run.

My Freeride 137 is blowing belts

The belt heat rises when you are running much full throttle in deep snow. The rear end of the sled goes far into the snow, augering.

The angle of the 137 sled cutting through the snow is steeper than a 146, but less steep than a 120 sled. The more the angle of the sled, the more cutting of fresh snow, adds more heat in your belt – Save your belt and gear to a lower ratio.

My own 800e x 120 x 2” has 21:49 (same as 19:45) and now I put more full throttle cutting fresh snow at 8000~7900 than I’ve ever done before and had lower belt temperatures. With the 23:49 I was still overheating the belt.

Any time you are on the throttle, augering through the snow with skis in the air – your sled is in a constant climbing state.

The Freeride having a more stiff suspension than a BCX or Regular Rene w/1.75, there is little to no suspension movement once you have good track speed going cutting deep fresh snow. A regular Rene with its adrenaline suspension is faaaaaaast in the snow as their suspension follows the contour of the fresh snow more fluidly.

Blowing belts on a Freeride 137? Soften the suspension to react better to the vehicle speed going through the snow and cause less augering angle and less lifting of the front end. Turn all springs down to a lesser force.

When you spend more time at full throttle in deep snow the belt gets hotter. Give the belt a break and gear according to what you are putting the belt through. Higher load use, lots of cutting fresh snow = gear lower

Always think about the belt, treating it belt properly through correct gear ratio that allows a lot of time at full throttle. That means gear down if your time in deep snow goes up and starting to blow belts.

If you are at 23 top with 1.75 and blowing belts from overheating then go to a 21 top and it will extend your time at full throttle in the snow. Belt temperatures will raise slower. If at 21 top gear you are still blowing a belt, but getting better mileage and time-out of it – gear down to a 19 top gear.

The belt is the connection between your engine and throttle. Gear down according to the load increase you are applying to the belt.

Belt – heat from fluctuating engine speed

Shane) I bought the tool to do my clutch alignment. After using it I check the clutches and I think the tool gave me a good alignment. Now my problem i was having was i didnt know how to clutch it to run good with the twin pipes trying different springs from my buddies garage and different weights, playing with clicker settings. On hard pack it was over over reving into the limiter 8500 sometimes, then in deep snow, down to like 7500. My belt and both clutches where always getting extremely hot and couldnt keep a belt in the sled anymore at this point.

Joey)The lowest temperature you will see on the belts regardless of cool to incinerating is when you get the engine to run at its rated speed.

The pulley faces draw heat away from the belt and dissipate it. Lower than rated speed, or higher than rated speed, the belt temperatures soar because the clutches in both scenarios stop shifting. Either engine speed result, the belt does not travel across the pulley face. The pulley can’t draw heat away from the belt and the clutch face is heated in a localized area. And its accumulative. Every time you hit 7500 the belt is staying in that location on the sheave face, track speed does not increase, temperature soars.

Need to calibrate the flyweight, primary spring and clicker position to achieve rated engine speed.

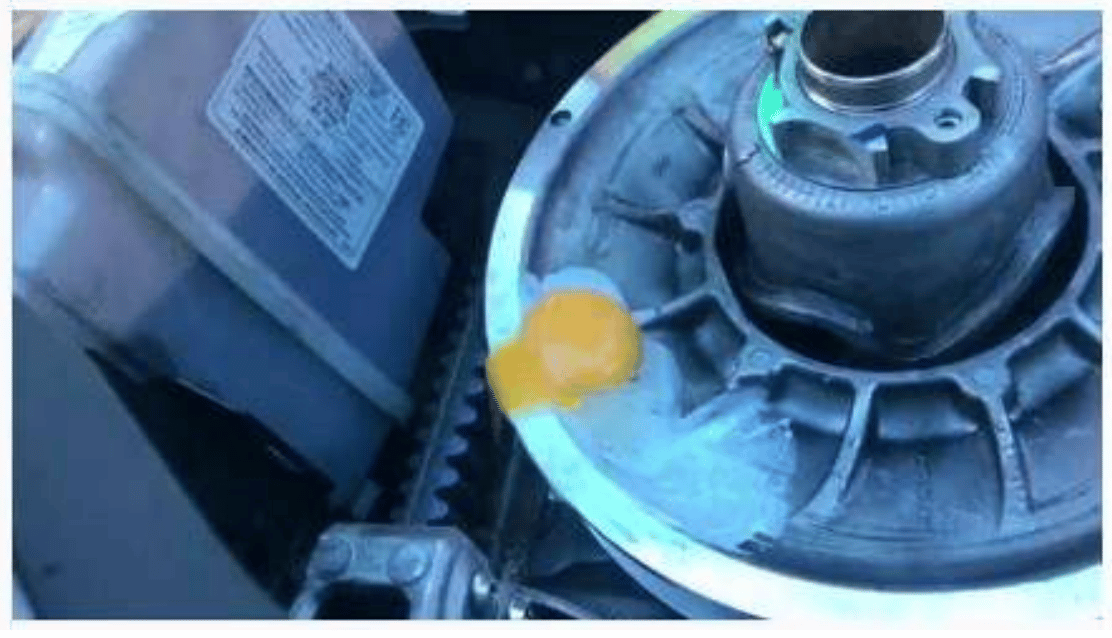

QRS quisine – Funny…sunny side up eggs

2019 Belt Chart