Engine Fitness – Engine has high miles. Compression check?

Question) My sled has about 6000 miles on it. What can wear, what can I look for?

Answer) With 6000 miles on your sled, how many miles does engine have? I want to know what kind of shape your piston rings are in. If your rings and pistons are worn out then it will be difficult to calibrate the clutch kit. The settings will work good when the engine is cold but when engine hot, then will not run good and lowering engine speed as a result. This could be an indication of the piston rings or complete piston needs to be changed.

Take a Cold vs. Hot compression test.

1] Start the sled and let it run for about 30 seconds and kill engine.

Put the compression gauge in the cylinder head and take compression with 5 PULLS WITH WIDE OPEN THROTTLE.

What are the values? (record the values)

2] Start the sled and let it run until the coolant is at operating temperature and flowing. Test the coolant temperature with your hand by touching the tunnel heat exchanger.

To achieve this operating temperature in a place where you cannot go ride the sled, “Remove the drive belt” so you do not burn any of the cogs in a localized area of the belt while the belt rubs on the clutch shaft.

OR, go take it for a run if you can and out there when engine operating temperature, shut it off and check the compression with

5 PULLS WITH WIDE OPEN THROTTLE.

What are the values? (record the values)

It does not matter if your gauge is accurate or not as long as you use the same gauge when cold vs. hot temps.

Indications of poor rings

cold compression – 5lb(35kpa) or greater difference from mag to pto.

Hot compression – 7lbs (48kpa)(or more less than when it was cold then you need rings.

Hot compression – 10lbs(68kpa) or more less than when it was cold then you need pistons.

Example:

Cold @ 145lbs (999kpa)

Hot @ 138 lbs (951kpa) or less than…

Value difference more than 10lbs (68kpa)

Engine Fitness – Refresh your pistons/rings

One thing I been stressing is if owners of sleds from 02~05 are keeping their sleds or owners with any 600/800 engine that has around 5000 miles, then check the engine compression cold vs. hot and ensure the engine is fit before you move forward and get a clutch kit. It’s tough to calibrate a kit or make a consistent clutch setting when the engine gets hot and compression values lower.

You will observe correct rpms when running cold or warm but as the engine gets hot, may observe rpms drift low; an example the engine runs 200 rpms lower at full throttle due to failing compression. (as vehicle speed increases)

If keeping the sled, then it is an “Investment” to freshen up the top end of the engine. Run the best piston you can for long life and that is usually the original BRP piston.

Engine Fitness – Leakdown test “engine compression” what does it do?

Cylinders never wear even as you know. Therefore, you will have minor deviations in the walls of the cylinders and as a result less ring seating occurs. The piston speed makes up for this deficiency as it passes the offending area quickly. Even with plated and SCEM (Boron Composite) cylinder walls that literally as hard as diamonds, you have these offending areas.

The leakdown test finds offending areas on the cylinder walls and can show the truest measurement of ring fitness.

It shows if pistons need to be replaced?…could be skirt collapsing?

Yes, of course…look in the corners where the skirts start and see if you witness and microscopic cracks. A magnifying glass helps as these a very tiny and often not able to be seen with the naked eye. Your Big Bro, Freddie Klies

Exhaust – Muffler caused engine speed change

Question) I put on this XXX can and I lost top end speed, what happened?

Question) I put this XXX can on and I lost peak rpms, what happened?

Answer) Sometimes an aftermarket muffler does not have the correct “choke” to cause the engine to run at its rated speed. I personally had a muffler installed that lost 1300 rpms at 10000 feet in Cooke City MT. I put the stock muffler back on and 8000, put a different muffler on and 8000 rpms. Put my muffler back on and 6700 rpms. Put the stock muffler back on and 8000.

When running the engine at full throttle, the exhaust pipe itself will see say 4.0 psi internal pipe pressure. When there is a change in your sled performance (lowering power and engine speed) the internal pipe pressure would be lower – 3.9, 3.8 psi, etc.

My advice to people who buy muffler “cans” – don’t get rid of your original stock muffler, just in case you need to use it again.

When going from low elevations to high elevations for the first time with your aftermarket muffler – always take your stock muffler along with you to the mountains to be able to rule out a muffler being part of an engine speed problem.

I have personal first hand knowledge that after putting a “tuned” muffler on, this 2014 800etec x 163 seen low peak engine speed. Regardless of clicking up the calibration screw on the primary clutch to increase engine speed – the engine just got more lazy. Put the original muffler back on and clicker back to original position and power by the hour 7900~8000.

Not all mufflers do this – this is information to help you sort out an engine speed problem to rule out a muffler contributing to low peak engine speed.

Jetting for engines of higher rpm than stock.

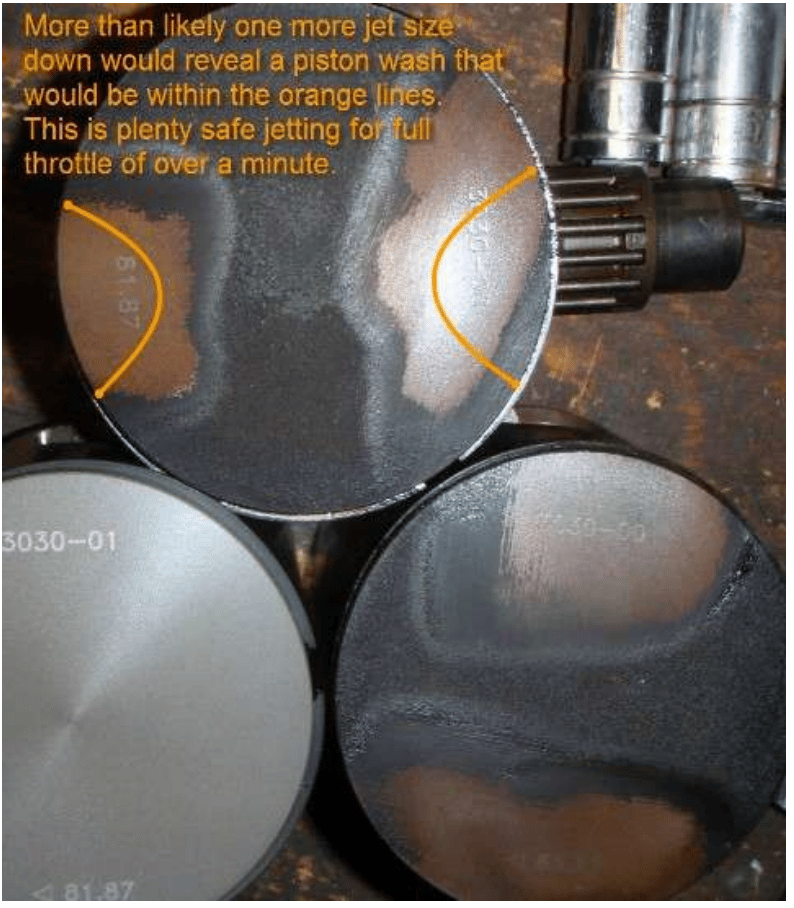

Engines that use high rpm pistons or are high rpm big bores; to get the engine with these mods to run at their full potential 8300~8500, the tuner has calibrate the carburetor jetting correctly for the engine to start to make correct combustion temperature to reveal the potential power the engine has after the rings are broken in.

If the engine is rich, it won’t run at correct rpm, the tuner will observe low rpms. A common rpm for a rich engine to run at will be near the rpms of peak torque which can be from 250rpm to 450 rpms low of the actual potential peak hp rpms. An example 8400 rpm engine with rich jetting calibration can run at 8000~8100. Once the tuner starts to get the jetting correct for the engine then the rpms will start to want to turn higher rpms.

I only recommend jetting with a borescope, like the PV-618 . The borescope is not a cost, its an investment. You learn to use this scope and jet calibrate wisely, nobody will ever tell you how to jet an engine, you will tell them how.

Thanks to: Al Shimpa, Freddie Klies and Dallyn Maxwell for jetting information.

Don’t be fooled by more hp = more flyweight because if the engine is making hp at a higher rpms then you won’t want to change the flyweight. Run the engine first, dial the jetting in then start to spend a dayride to get the flyweight dialled in if-needed.

Engine Braking – Jake Brakes of snowmobiles

Question:HI Joe In the off season I put a newer non-ported flex edge 2.5″ track on from the stock 2.25″. Long story short, first ride this season the sled feels like it is back shifting really abruptly ie when I let off the throttle the sled slows down alot almost like the brake is on ( I’ve verified the brake is not rubbing) I also noticed it seems to hold me back on down hills and the clutch stays engaged more that before also. I did a top end (new pistons/gaskets) at the same time as the track change. Should there really be much difference in engine holdback just going up .25″ in paddle size that I’m having some sort of clutching issue?

Answer: Did you change the gearing lower for the new track size?

Engine braking is based on

Maximum engine vacuum

Secondary spring start force

Primary clutch ramp start angle (first 1/5th of the ramp)

The engine should idle at 1100 to 1200 rpms. IF the engine is idling higher than that like 1400 say, the engine braking strength will be lower than at 1200. Maximum engine vacuum is at the lowest idle speed. (Etec can only be adjusted by BUDS laptop)

Secondary spring – can increase the start force

Belt tension – Maximum engine braking is when you can make the belt deflection be not quite as tight as this but dang close.

https://www.youtube.com/watch?v=VNVv-jOzaIE

Engine speed off at high elevation – no matter what clicker number

alex####@yahoo.com Dec 8 2019

Question] I bought a 13 skidoo sumit last year and it looks like he has put on your NC-D2 secondary clutch kit with the yellow and orange dots and dont remember what is in the primary but it worked great in Michigan then I went to togwotee and could not get it running right I changed up my weights and it would run good then fall on its face and then I would change my weights and felt like it lost all its power. I was just wondering what I should be running out west and if I need different springs or what .. I weigh about 250lbs with all my gear

Reply to Alex] Hi Alex.

What muffler are you running? Aaen or Bikeman?

Any engine mods?

What weight did you run for Togg? What elevation were you running at? What grams did you use? Did you try changing the clicker?

What is the color of the primary spring?

**** What was the engine speed at full throttle? ****

Thanks joey

Reply to Joe] Subject: Re: skidoo – alex’s 13 summit

I am running a bike man, I dont believe the previous owner did any engine mods to it, we were riding at 9000+ in elevation I changed the clicker from 1 to 6 and did not seem to make a difference I am going to pull my clutch off today and will get the rest of the information for you

Reply to Alex] Alex) I changed the clicker from 1 to 6 and did not seem to make a difference

Joe) this is why I asked if you had an aaen or bikeman muffler.

Get a stock muffler and put it on there.

Im tired of dealing with these bikeman garbage cans. These facts you present are more than a coincidence, which is why i specifically named-names on the garbage cans. So many over the last 6~7 years, im tired of getting the blame for an owner not being able to make correct engine speed. Im going to make the claim the bikeman muffler does not have enough choke for high elevations to make the correct internal pipe pressure to make the correct engine speed.

IF you made a clicker change from 1 to 6, that is the equivalent of 1200 rpms, like 30 hp difference [5hp for each clicker number]. I bet that bikeman pipe would not allow your engine to run over 7000~7200 rpms tops.

We build the clutch kit on a bone stock engine. The engine has 150hp down at sea level, it has 95hp at 8500 feet. All you have to do is change the flyweight to reflect the engine power decrease and you will always get 7950 rpms.

***FLYWEIGHT grams used IS…a direct representation of engine torque. Not only does flyweight reveal the amount of engine torque, but it also can reveal what the engine peak power rpms is at ***

SO, when the engine power shape does not conform to the linear power loss from air pressure loss as elevation increase, then the “peak engine rpm changes”. The engine wants to run at 7950 rpms at low elevation but now wants to run at 6800 to 7200 rpms at high elevations.

If you went from clicker 1 to 6 and had little engine speed change then the engine power shape is the problem. You do not have a clutch kit / setting / tuning problem. Your engine wants to run what engine builders call “early” and not at 7900 anymore. It wants to run at 7200 rpms.

Put the stock muffler back on. If you do not have one, then find one, borrow one or buy one from ebay or somewhere and put it on.

Its not the clutching. Im making the claim its that p.o.s. bikeman garbage can.

Did your engine have any strength over 7200 rpms, yes or no?

Joey