The Freeride itself vs. a softer suspension sled (X, Adrenaline, SP…etc) models are a substantive difference in suspension calibration – The FR being a “stiff suspension sled” vs. a non-FR, “softer suspension” sled.

The Freeride to which the foundation of its design intention is for flatland, hard surface, high g-force bumps, high speed shock shaft velocities; using extra firm shocks and stiff springs to on-purpose, dampen correctly for severe load variations.

The Freeride calibration is “over dampened” for the rear suspension to be able to keep a best contact angle when traveling through fresh-deep-snow (regardless of snow set).

For the reader – The information is more tailored to the category of use; higher percentage of off-trail than on-trail.

Lack good launch (excessive spin)

KB) Is your custom clutch kit the answer to my problem child 2014 Freeride 137? This machine lacks a good “Launch”and seems to go through a belt every 500 miles. I am only a ditch banger usually looking for the deepest snow or toughest places to break trail. What can I expect out of your clutch kit and helix. Is it very different than the factory Freeride clutching??

Joe) Ermm, Ditchbanging and deep snow riding are two separate categories of riding. This is the problem – A ditchbang sled being used in deep snow to when the suspension is not calbrated for breaking fresh with the capacity of a softer suspension sled. The Freeride 1.75 and 2.25 sled is the hardest of all the sleds to get up in the air because of the rear suspension springs are strong. It is difficult to get the 137 chassis to react to engine torque compared to a softer suspension like an X model or renegade or shorter 120 length.

If you have the torsion springs softer and low speed valving on the shocks turned out a bit – then she should do not bad doing a harder launch.

Stiff suspension with little to no sag “set in” are difficult to hook up compared to a softer suspension sled.

A softer X renegade 1.75 can have harder acceleration than a 1.75 Freeride because when it comes to accelerating on snow the softer suspension “X” or Adrenaline model can hookup better with less track spin than the FR chassis. The other facts of the softer suspension is having stiffer suspension on deepest of G-out bumps when ditch banging, hitting driveways, doing high jumping, landing slight or flat angles.

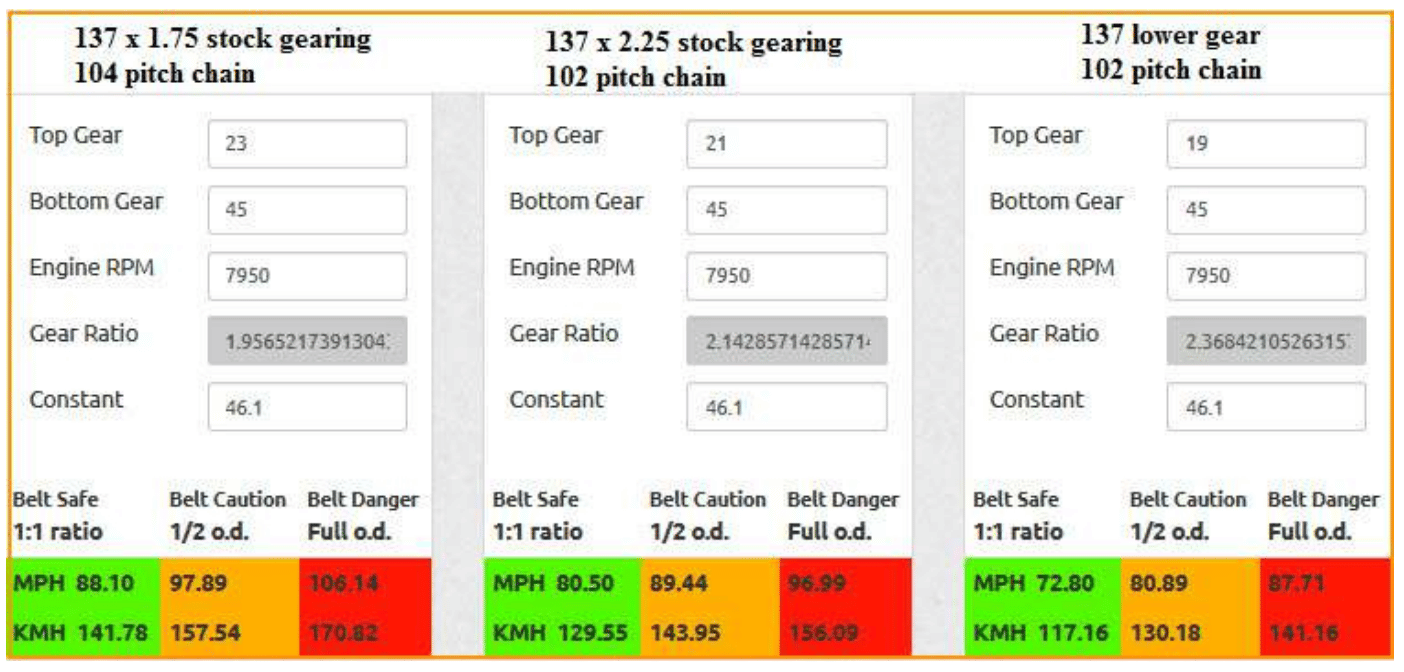

For the 137 x 1.75 and 2.25, If you are always looking for the most tough place to break fresh snow, then gear down and get the track speed up when you are on the throttle.

Bar-none the way to get the sled to go better in the snow is to have softer suspension settings and gear down a few teeth. The Freeride “augers” in the snow, the back end of the sled is down in the snow compared to a softer suspension sled.

Gearing changes

Justin) I see I can go to 21-49 gearing and keep my 104 chain is that going to be to low and will I still get 80mph or so out it. Only reason I ask is because I have a buddy with 21-45 and don’t really notice much of a difference between the 23 and 21

Joe) 21:49 and 19:45 are the same ratio.

Where you see the difference is in deep snow.

When you are augering through the snow and have a lower gear, there is less time lag from your thumb to the whirl of the track. When you are driving in deep snow breaking fresh, listen to the “howling” or the “whirl” of the track. As you press on and off the throttle the “whirl” of the track closely follows your happy thumb. With a taller gear there is a lag between thumb and track whirl. A lower gear has more burst energy to the track to get the sled on plane.

If you do not notice the difference between 23 and 21, you have to drive a little bit harder in the pow pow.

joey

Taller or lower top gear (have 21 top)

Big “G”) im wondering if i am loosing track speed in deep snow by having a 21 top gear, could i go 22 or 23 to get higher track speed?

Joe) Aaen’s rule of thumb says “gear as tall as you can without losing acceleration” which includes when you reduce throttle and the track speed falls off, then back on throttle to regain “accelerate” track speed again.

All i know is, lower gearing gives “track speed staying power” so when you are augering through the snow, a lower gear ratio is easier on the belt and will hold track speed for a longer period of time.

When it comes to a stiff suspension-Freeride model, if you are in very deep snow even when the back end is down quite a bit and augering through the snow, a 21 will run at a lower temperature than a 23 top gear. A 19 will run at a lower temperature than a 21 top gear. For every 1 tooth down you lose 4mph on top end but gain for “staying power” for track speed.

With “X” gear, say you achieve 45mph track speed. When cycling the throttle or a severe load change, hump or dip or the combination of either load change with throttle position can lose up to 7mph track speed. Every time back on the throttle, the clutches have to recover 7mph track speed to get back to 45mph.

Go one higher gear “X+1” and the track speed loss can be 9mph. Every time back on the throttle, the clutches have to recover 9 mph track speed to get back to 45mph, if it can.

Go two higher gear “X+2” and the track speed loss can be 11mph. Every time back on the throttle, the clutches have to recover 11 mph track speed to get back to 45mph, if it can. Continue doing this non-stop over time, 10~15 minutes and how much track speed did you have to regain in work accelerating in that time?

The cumulative effect in having to regain more trackspeed, the clutches will eventually see higher temperatures and get to a point where you will see engine speed loss – going less than 7900 @ full throttle. (7800, 7700…etc)

You end up spending more energy accelerating the track to get back to maximum track speed than spending energy “maintaining” the track speed you get.

Get the clutch kit dialled in with the current top gear.

You can allow engine speed of 8000 rpms and let it bog down (pull down) to 7900 on its peak. If you see 8050, then add another ½ gram and that will be about it. From that point on the engine will tach at 8000 and pull down right on 7900 and float around 7900~7950.

When you get your 7900~7950 rpms, then monitor your track speed – if you cannot see the speedometer, then listen to the whirl of the track – get used to listening to that sound of the track whirling increase and decrease. There will be a time you have listened to it enough that you notice the pitch sound of the track and know what track speed is happening.

After you have your sea-legs with the current low gear – then go to one taller and repeat the procedure.

Will you have as good of track speed staying power?…Just might. I dont know, its your sled and your suspension settings.

Freeride back end goes deeper in snow

Phil) Why does my Freeride go down deeper in the snow than my buddy’s summit?. We have 154’s.

Joe) The reason the track on your sled goes down and carves a deeper slot is becaue it’s a “Freeride”. You have the most stiff suspension a sled can have other than a race sled.

Example; The softer X and SP sleds have softer springs and valve settings than the FR. They have the ability to transfer and distribute weight more evenly across their rail than the FR. The suspension that allows the chassis to gobble up engine torque and place it properly in the rear suspension does a more efficient job of converting power to forward motion, and will immediately pull away from the FR (stiffer suspension sled)

Going across a meadow; the softer rear suspension absorbs-smoother, the thousands of bumps that you hit OR when going across the snow covered meadow or up a snow covered steep climb; there is a continuous push back on the rear suspension by the sled cutting the wave of snow oncoming to the sled. The snow being cut is pushing back on the rails. The softer suspension sucks up this cutting action and transfers it to the rear torsion springs. The rear torsion springs compress and the rail position is more flat going across the snow than a stiffer rear suspension that’s not giving. The low speed shock valving (low speed valving meaning the shock travel is slow when stroking in and out as the sled goes across bumps – ripple bumps, small hills, dips, cutting new snow) The low speed valving is stiffer on a Freeride.

When the rear of the suspension wont “Give” and allow the suspension to transfer small bumps – there is only one place the sled can go and that’s with its rear end down deeper in snow. Now every bump you do hit is pushing UP more on the sled, the bump is lifting the sled. The softer rear suspesion, the bump is lifting on the suspension and “Gives way” to the bump – the chassis stays more level and does not fluctuate up and down as much.

The Freeride suspension calibraiton is designed for when conditions change radically in a short period of time. Like going through big G-out bumps, deep and sharp where snow is hard, trail is hard, hard pack, set up late season snow.

The springs control the ride height and the angle of the chassis as the sled encounters bumps and full throttle applications. To get the Freeride to cut the snow better like a softer suspension summit – then can lower all spring forces, turn out the low speed shock clickers – all making the suspension softer. I’ve done this on Freerides that ride with me – we’ve got a handful of them to use the “next softer” suspension springs. This season 2017, im setting up my friend’s Freeride 137 with the next softer springs front to back. After he rode a 14 with the settings we come up with, he was amazed the difference in deep snow for improved handling.

The rear suspension is in a way, like a secondary clutch – the rear suspension being a “Convertor” of engine power to the ground.

The chassis with a softer suspension (Adrenaline) or (Sport) or (X) model, each one has the a better ability than a stiffer suspension Freeride to transfer and distribute its weight more evenly across the rail when accelerating.

The suspension that allows the chassis to gobble up engine torque and place it properly in the rear suspension does a more efficient job of converting power to forward motion, and a softer suspension in fresh snow will immediately pull away from the FR(stiffer suspension sled) at just about any type of snow set.

That kit will solve some issues and clean them up. You can make the sled work even better by softening all the springs. The spring control the “ride height” of the sled, you will have a bit more ability to have “sag” when you step on the sled.

Take your low compression clickers on the shocks and turn them out, make the low speed valving softer – this will allow the sled to follow the contour and set of the snow better – softer setting allows more flotation on the snow at high-part to full throttle.

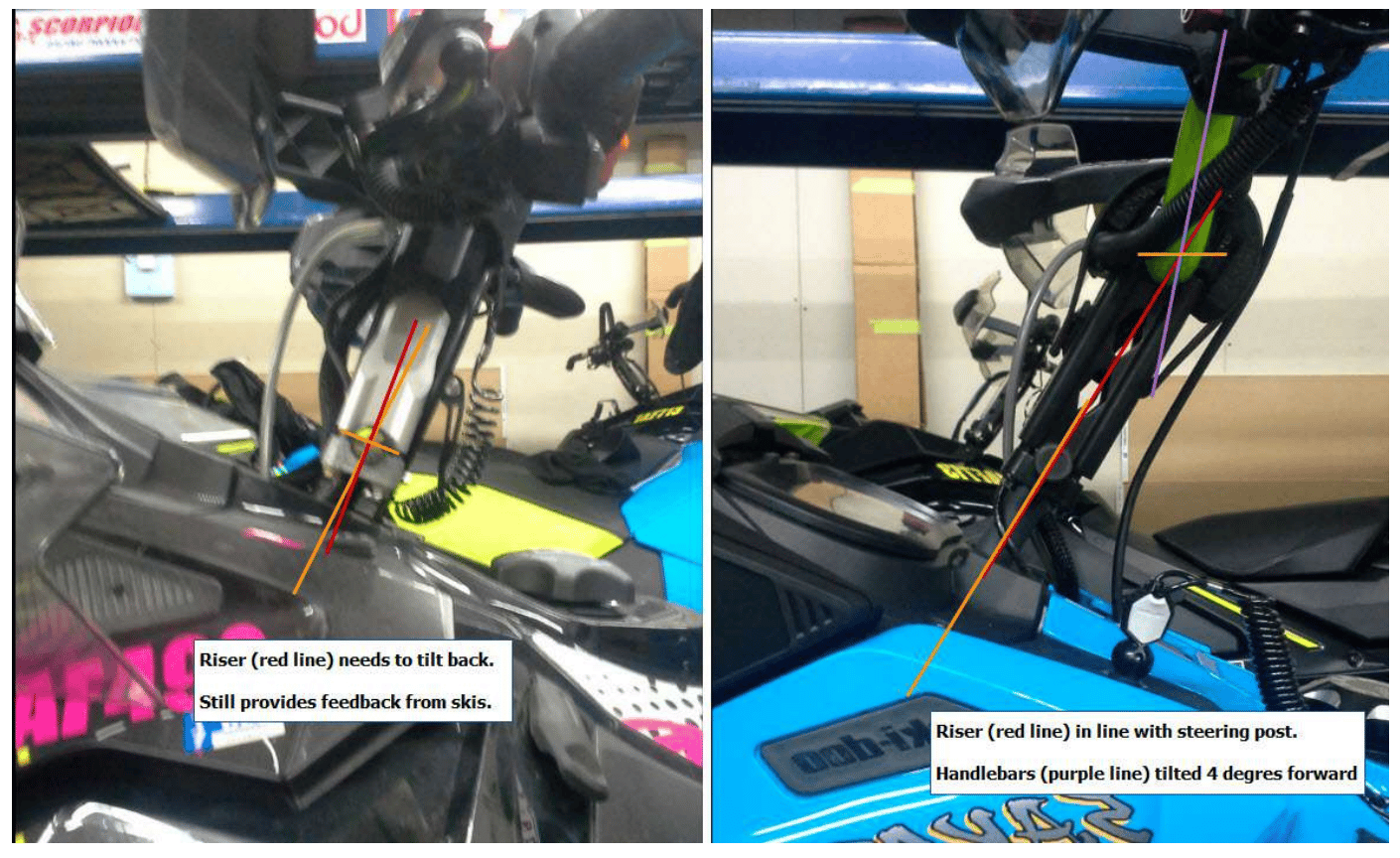

Carl Kuster handlebar setup tip

Want to give your stiff rear-suspension Freeride a help to lift the skis in the air? Follow Carls guide on tilting the handlebars back from their forward “trail riding” position – to either inline with the steering post or a few degrees towards you, tilting back.

This will help yo place your body in a better position on the rails to lift the sled when you hit the throttle and/or want to countersteer.

From that point on, you can adjust your rear torsion springs to a softer position to allow the chassis to react to you pressing the throttle and your body weight helping the track engage the ground, in-effort to lift the front of the sled.

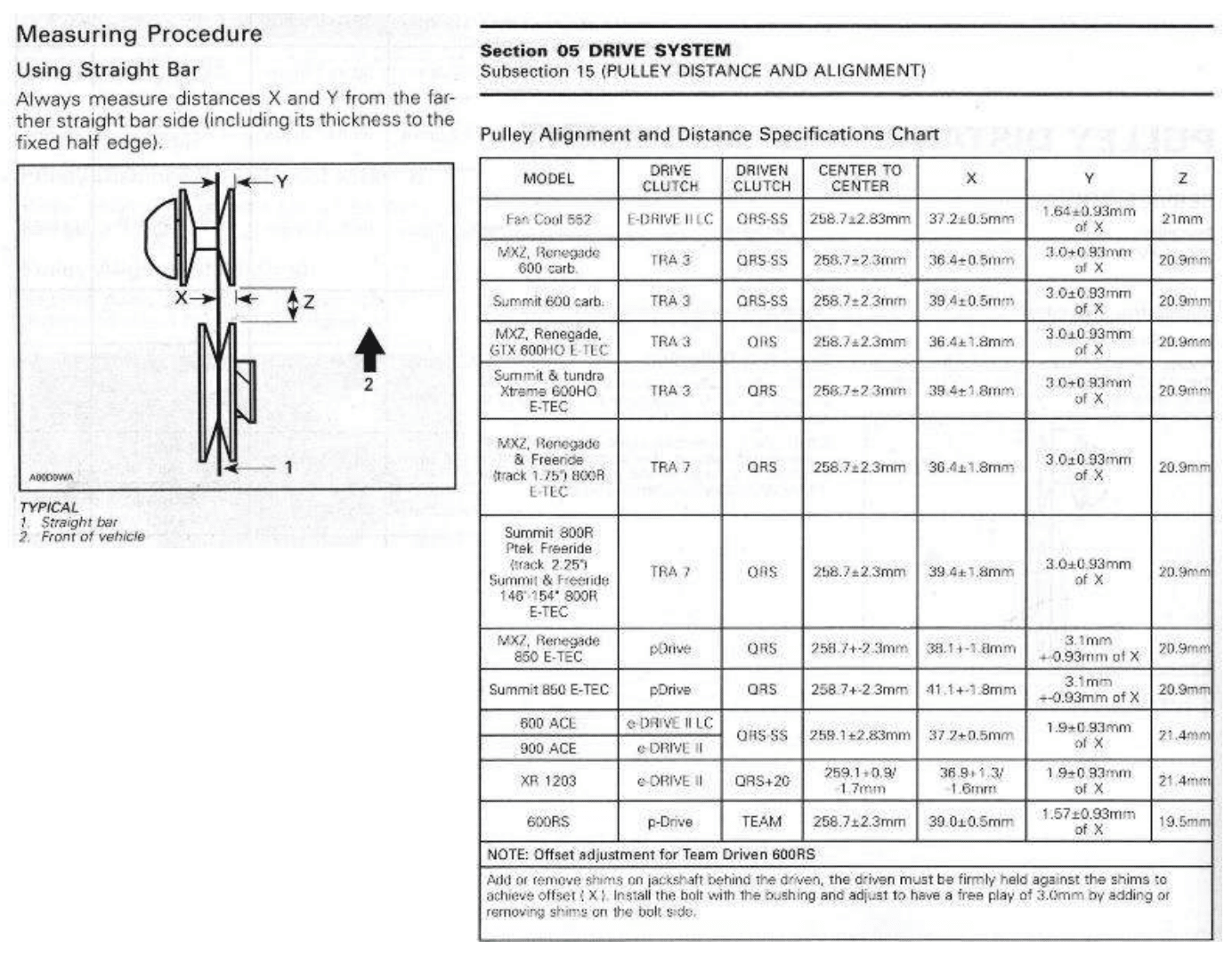

2017 Clutch alignment

The taller geared 137 x 1.75 (23:45) has a narrower “X” alignment than a lower geared 137 x 2.25 track

Gearing a 137 x 1.75 & 2.25 (reduce belt temperature)

This “Green” color on the side of the belt is still there because the belt has not been overheated. When you overheat the belt, the tinge of the green color gets masked by brown and continue to overheat – black. Your belt will eventually release the adhesion chord, popping out and belt fails.

If you have a 137 Freeride x 1.75 and blowing belts from overheating and spend 80+% of your time, breaking fresh snow and making your own trail; keep this thought in the back of your head like a small guilty conscience – remember, you have a sled with an overall suspension calibration that’s working against you for running in snow where the back end of the sled is augering deep.

If you are not going to adjust the rear suspension to get it to “Give” more (have more set-in) for breaking fresh snow, then you have to give the belt a break and gear down more.

If you are not worried about top speed out on the flats, then choose a lower gear. The orange box gives you the safe maximum track speed you can go and not put the belt in the damage area – the lowest area (highest ratio) of overdrive in the secondary clutch.

Gearing down will allow the belt to ride higher in the primary at a same track speed. The belt will travel across more of the sheave face. More sheave face exposure will let the primary do its work, drawing the heat away from the belt and give more leverage through the gear/chain to the drive axle. The clutching will do more work and reveal less belt heat. The belt speeds will be higher and have less torque pushing on the sidewall of the belt.

My own test guys have 19:51 gears in their Freeride 2.25 tracks. We do nothing but boondocking, sidehilling and technical riding. The only trail we use is the trail we made to go in somewhere – us coming out.

Just saying, don’t be afraid to gear lower if you are not worried about top vehicle speed.

Question) Do I have to change torsion springs?

Joe, a little research shows that the Freeride 137 and the Renegade XRS use the same rear spring. 503192104 RH 105 LH.

The Renegade X and the regular Renegade use the same rear spring. 503193159 and 158. Do the rear springs need swapped? or also the front track shock also?

Answer) some theory for you and then you decide on your own facts.

2004-Race manual – Section 3 – Chassis preparation pg 03-2

Weight transfer is essentially the shifting of weight to the track for better traction during acceleration. As we apply torque from the engine to the drive axle, the torque is transferred to the track and pulls it forward. That energy enters the suspension system at the rear axle and tries to pull it forward. The rear arm is a pivoting or sliding linkeage that only provides vertical forces at the rear of the chassis, therefore, none of the force (in the rear axle) enters the chassis at the rear arm.

During acceleration the rear arm will want to compress and the front suspension will want to extend (possibly raising the skis off the ground). Because of this pivoting effect, the rear spring and preload will also affect weight transfer (to a lesser amount than center arm changes) A softer rear spring and/or less preload will allow more weight transfer to the track and less ski pressure, while stiffer rear springs and/or more preload will allow less weight transfer and more ski pressure.

The rear suspension, the center arm is as a pivot point.

Pg 03-3

The main function of the rear arm is to support the weight of the vehicle and rider, yet provide usable travel to absorb bumps and jumps. The springs are chosen depending on the linkage design of the rear arm and the intended load to be applied.

Stiffer springs will be used on vehicles intended to carry heavier loads and on vehicles that plan to encounter large bumps, while vehicles used for lighter loads and on smaller bumps will use softer springs.

Shock absorber valving and the type of shock used will also effect weight transfer.

Extracted tuning considerations

Weight transfer is essentially the shifting of weight to the track for better traction during acceleration. The rear arm is a pivoting or sliding linkage that only provides vertical forces at the rear of the chassis, During acceleration the rear arm will want to compress and the front suspension will want to extend (possibly raising the skis off the ground). Because of this pivoting effect, the rear spring and preload will also affect weight transfer (to a lesser amount than center arm changes) A softer rear spring and/or less preload will allow more weight transfer to the track and less ski pressure,

The rear suspension, the center arm is as a pivot point.

The springs are chosen depending on the linkage design of the rear arm and the intended load to be applied.

While vehicles used for lighter loads and on smaller bumps will use softer springs.

Shock absorber valving and the type of shock used will also effect weight transfer.

Far as I know the Rene XRS only has the adjustable shocks on the spring order models.

FR x 137 standard rear torsion – 503192104R, 503192105L

Rene XRS standard rear torsion – 503192104R, 503192105L

Does the Rene XRS have softer shock valving (lo & hi speed) yes or no?

Are the Rene XRS shocks able to have their lo-speed shock valving tuned manually to a softer setting (yes or no?)

During acceleration the rear arm will want to compress

…It wants to compress but does it? (yes or no)

…when you stand on the sled, does the rear of the sled have set-in (yes or no)

Foundation) If you can change the shock valving (by factory provided controls-knobs/screws/adjust nuts) but the valving is still not soft enough to transfer weight under full throttle (we’re trying to break fresh snow here – not ditch bang)

Q) then what means do you have available to allow the “chassis” to transfer weight when under full throttle?

A) the next softer spring OR get a shock tuner to soften up the shock.

***

Foundation) If the rear arm is not compressing as the vehicle (Freeride) cuts through fresh snow, the rear end of the sled will be lower in the snow, the bumper will be deeper in the snow than a vehicle which has suspension movement that can cut through snow with more flotation, lesser angle.

Q) Which change is easiest to do, to learn, if you are moving in the correct direction to apply a Freeride that is intended for severe hard surfaces to the task of traveling better through fresh unbroken snow?

A) The rear torsion springs to the next-softer spring.503192137R, 503192136L. Freeride softer torsion springs

Freeride 137

Standard – 503192104 RIGHT, 503192105 LEFT. Wire diameter 9.525mm square. Opening angle-90. Constant Newton meter/degree = 1.50

Softer 503192137 RIGHT, 503192136 LEFT (BRP dealer prices – $64.99/each CDN – $49.99/each USD) Wire diameter 9.0mm square. Opening angle-80. Constant Newton meter/degree = 1.35

***

Freeride 146/154

Standard – 503192137 RIGHT, 503192136 LEFT.

Wire diameter 9.0mm square. Opening angle-80. Constant Newton meter/degree = 1.35

Softer 503192080 RIGHT, 503192081 LEFT (BRP dealer prices – $64.99/each CDN – $49.99/each USD)

Wire diameter 8.85mm square. Opening angle-80. Constant Newton meter/degree = 1.27

Commentary on softer rear springs

Above, i’ve listed the prices out for rear springs (torsion springs) from a BRP skidoo dealer. These springs are economical to buy and will help the sled transfer – the chassis “transfer” your body weight and engine torque when you hit the throttle. If you are having a hard time to hook-up when you hit the throttle OR you want more snap out of the bottom end, then go to the next softer torsion spring.

A rider says to me: I want more snap out of the bottom end (137×1.75)”.

I start to ask about the rear suspension settings.

-What are the torsion spring adjuster blocks set on? 1(softest),2,3,4(hardest)?

-What is the rear shock low speed valve setting on? Clicker turned (out) soft, to Clicker turned in (hardest)

-What is your rider weight with gear? (body weight + 30 lbs/14kg)

We analyze the clutching is snappy. The “track” not sled, does have a lot of response when on/off the throttle. Being the rider is 170 lbs with gear; the rear suspension cannot convert the engine torque to the track because the settings are too stiff for the rider weight and the small lug 1.75 track. The chassis is “locked out”. The rear suspension is not moving. Only when he gets a 240 lbs rider on the sled, does the sled move down 1 inch. What?….1 inch?

I further inquire to the settings and the rider says the previous owner put 600RS rear torsion springs in the 137. Ermm…buddy, from our experiences with going this route and you are doing 80% off trail breaking fresh snow – your belt and clutch temperatures are going to be high and going to blow many belts. For your rider weight, you have to get a softer rear spring in the suspension to allow the suspension to do its job.

The rear suspension “transfers weight” and allows the sled to have better flotation in snow. You continue with these stiffer springs and will be doing nothing but augering in the snow and the sled is harder to control in deep snow. You will end the day tired because of so much rider input.

Rider weights with gear of less than 200 pounds – these softer torsion springs are going to benefit you to get the sled to accelerate harder, spin less and be easier to control on a sidehill situation.

If you are not going to remove the shock and have it valved softer in the “low speed” portion of the valving then this softer torsion spring is the next best move.

Controlling the vehicle in a sidehill maneuver will be easier as the sled will have less tendencies to “wash out”, wanting to point uphill.

Basic Ski lift for stiff suspension

Bar- riser MUST be (in line) with the steering post. (this forces the rider in a better position on the rails) (LOCK IT DOWN)

With riser tight – loosen Handle- bar and set either at 0 degrees or 2 degrees or maximum of 4 degrees forward – LOCK DOWN TIGHT

Front coil springs on low to 1/3 tension

Front shock clickers on low to 1/3 adjustment (need front end to sag a little)

Rear suspension center shock coil spring on 1/3 to 1/2 tension

Rear suspension center shock clicker 1/3 to 1/2 of full adjustment

Limiter strap full out, loose, last hole

Rear torsion springs on low

Rear/rear shock clicker on lowest setting to 1/4 adjustment

You need a bit of “Set in” on the sled to be able to lift the skis when you are on the throttle. The suspension NEEDS TO WORK AND do its job of transferring engine torque and not just suspending the chassis in the air. You dont allow the suspension to work and do its job – then dont expect a wheelie or catwalk – you can expect the track to dig into the ground and the vehicle have poor acceleration. A softer suspension setup will eat-your-lunch.

Riders less than 220 lbs have a harder time to lift the skis with a stiffer suspension Freeride no matter 137, 146 or 154. You dont have the body weight to compress the forces of the springs and stiff shock valving even with the addition of engine torque when pressing full throttle. A lighter rider must make the suspension have set-in by making the spring forces lower – either by settings or the next-softer springs.