Helix – Helix and engine power peak

Exhaust pipe temperature influences the RPM that peak horsepower occurs at. The engine starts, exhaust gas starts to enter the pipe. Heat transfers from the exhaust gas to the wall of the pipe. The pipe starts to warm up. More throttle overcomes more load, there is more exhaust gas flowing through the pipe, the pipe becomes hotter. Keep going full throttle for more time and the whole exhaust pipe is heated to its maximum temperature. The exhaust pipe temperature will stay at maximum until there is a condition change like the driver reducing throttle. Reduced throttle, the pipe temperature naturally lowers because there is less exhaust gas to keep the pipe heated.

The engines power peak moves with exhaust pipe temperature. On an average sled, let’s say an 800cc model where its power peak is at 8000 rpms. When engine running, the driver brings the engagement speed up and starts to move the sled, the pipe temperature is between 400 to 500 degrees. The driver presses full throttle, the HP peak is likely to be around 7700 rpms even though the engine revs to 8050~7950~8000 rpms. As the time-at-full-throttle increases, the internal pipe temperature increases to around 1000 degrees F. The power peak of the engine moves from 7700 to 8000 rpms.

Driver does full throttle in a pull, pulling up a hill or driving down a straight stretch; pipe is heating, power peak rpms is increasing. Driver reduces throttle turning out from getting stuck or to slow down to an approaching corner. Less throttle, means less pipe temperature and the “power peak” moves to a lower engine speed.

The horsepower peak rpm shifts according to pipe temperature.

A multi-angle (progressive) helix takes advantage of the engines moving power peak. As the snowmobile idles, the exhaust temperature is cool and the engines HP power peak rpms is lower. Because of this lower power peak rpm, a bigger helix “start angle” can be used to load the engine appropriately (notice I did not say the word “harder”), taking advantage of the lower power peak. As the exhaust gas heats up from a bigger throttle position, the snowmobile track speed is increasing and the helix angles used, can start to lower. As the speed increases, the secondary wear button or roller travels farther down the helix to a progressively smaller angle.

As the clutch shifts out, track speed getting faster, the helix angle is lowering, matching the moving power peak of the engine.

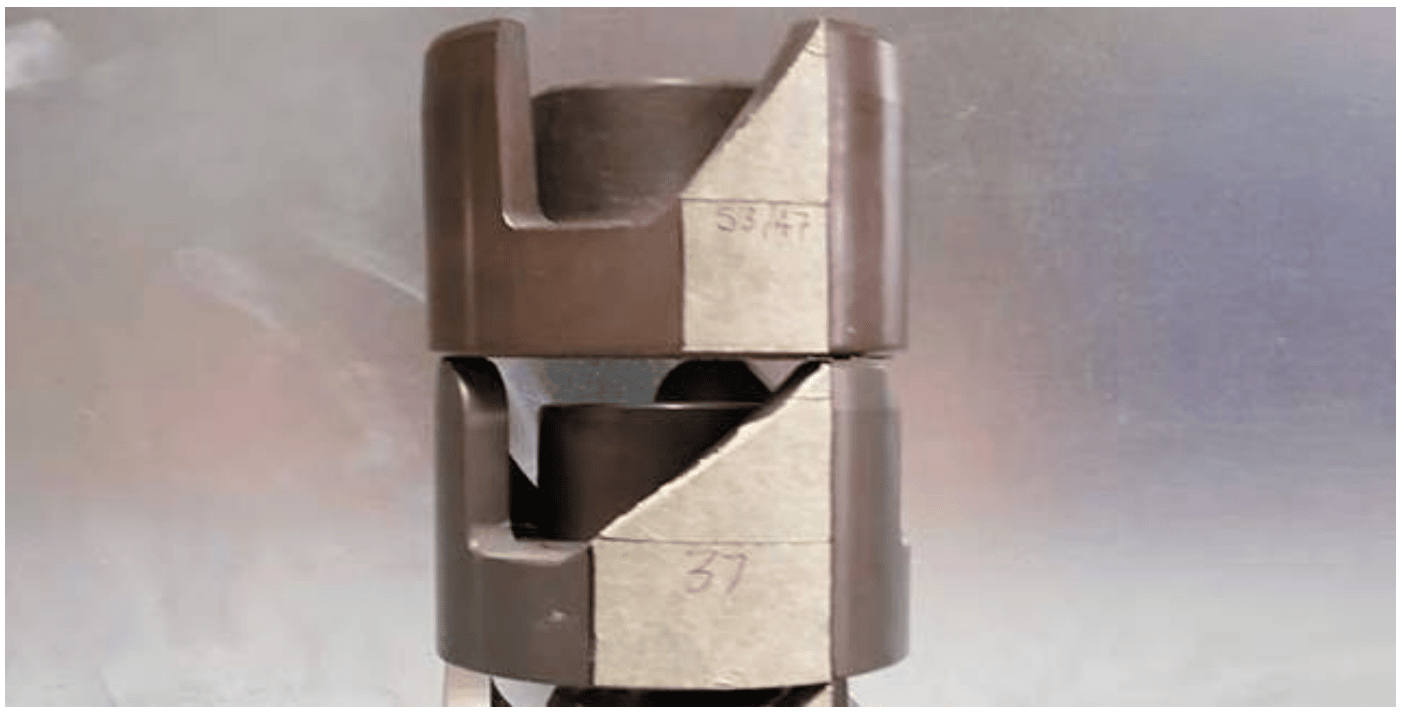

Helix – Straight angle, dual angle, progressive angles, step straight, step progressive.

A straight angle helix or single angle helix is a helix formed by two lines sharing a common end point. Example 47 degree helix on a sled geared for 100mph at full overdrive. At the top, the start of the helix is 47 degrees. The top of the helix is zero “0” track speed. The bottom of the helix at the end point is 47 degrees. The bottom of the helix is at maximum track speed (100mph). The helix angle is 47 degrees from start to finish. Does not matter what track speed, 37mph, 14mph, 98mph, 54mph; at every mph, 47 degrees is being used to transfer engine power to the ground.

You might have heard the phrase “Dual angle helix”. A dual angle helix is just that; “dual” expressing two angles. It was common to see in the late 80s to late 90’s “dual angle” helixes. Example 47/44. If the gearing allows 100mph at full overdrive, the 47 degree goes from 0mph to 50mph; the helix abruptly transitions (and you can see the transition) to 44 degrees. The 44 angle goes from 50mph to 100mph.

Tri Angle. A tri-angle is just that; three (3) discrete angles you can see each angle. Example 36/34 has 3 degrees, 36, 35, 34 degrees. If gearing allows 100mph at full overdrive, the 36 degree angle goes from 0mph to 33mph. The 35 degree angle goes from 33mph to 66mph. The 34 degree angle goes from 66mph to 99~100mph. You can run your finger down the angle path and feel the transition of each angle, (The vertex) and see where one angle transitions to another.

Progressive angle; a class of angles turning about a point between two lines [top of the helix path to the end point of the helix path] Drawn angle lines overlapping one another, trimmed to make a composite “curve” of angles. Industry terms are “Progressive” or “Smooth progressive” or “Full progressive”, the terms trying to describe the helix has no visual transitions from one degree to the next.

Example 47/44. The angles are 47, 46, 45, 44. If gearing allows 100mph at full overdrive then the angles used are…

47 from 0mph to 25mph, 46 degree from 25mph to 50mph, 45 degree from 50mph to 75mph, 44 degree from 75mph to 100 mph.

How many angles are in a 50/40 progressive helix? 9/10 people will say “TEN”. Wrong! There are 11 angles. Count the angles on your fingers. 50, 49, 48, 47, 46, 45, 44, 43, 42, 41, 40 = 11 degrees.

100mph / 11 angles = 9.1mph per degree.

50 @ 0~9.1mph.

49 @ 9.1 to 18.2mph.

48 @ 18.2 to 27.3mph.

47 @ 27.3 to 36.4mph.

46 @ 36.4 to 45.5mph.

45 @ 45.5 to 54.6mph.

44 @ 54.6 to 63.7mph.

43 @ 63.7 to 72.8mph.

42 @ 72.8 to 81.9mph.

41 @ 81.9 to 91mph.

40 @ 91 to 100mph.

Question; what degree is used at 61mph?

Answer; 44 degree

Question; what degree is used at 20mph?

Answer; 48 degree

Question; what degree is used at 88mph?

Answer; 41 degree

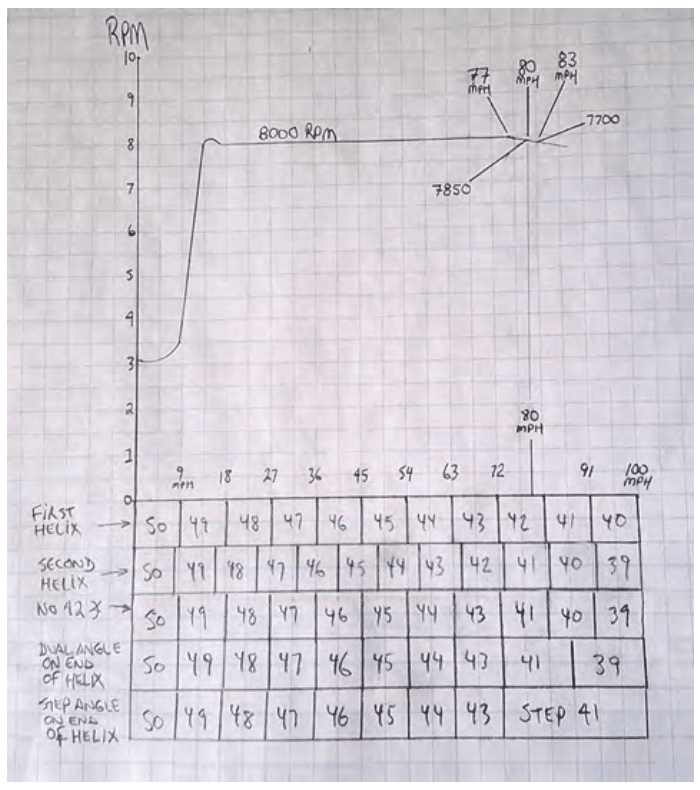

The secondary clutch is using a 50/40 helix. Engine speed is rated at 8000 rpms. Take a full throttle run to top speed. You see at 77mph, the engine speed starts to lower. By 80mph the engine speed is at 7850 rpms. By 83mph the engine speed is 7700.

Question; what degree is used at 80mph?

Answer; 42 degree

Question; IF a rule of thumb (in this) is 1 degree can change engine speed by 150 rpms, THEN what degree is needed at 83mph preventing engine speed lowering from 8000 to 7700 rpms?

Is the answer 40? 39? 42? 36? 44?

Aaen ramp rule: The smaller the ramp angle, the higher the side force

IF the engine speed is starting to drift low away from 8000, THEN the primary clutch is pushing too hard, overcoming the belt side force settings of the secondary clutch. To put more side-force into the secondary clutch you can change the helix angle “At-that-track-speed” the engine speed is drifting low. Only change the helix angle(s) at the problem track speed.

The sled sped up adequately with correct engine speed to 77mph track speed and then engine speed started to lower.

That means the helix angles 50, 49, 48, 47, 46, 45, 44, 43 allowed the sled to speed up adequately with correct engine speed and are sufficient. At 80mph the engine speed was at 7850 rpms using 42 degrees.

Tuning objective is to raise engine speed back up to 8000 at 80mph. IF want to raise engine speed at 80mph, THEN lower helix angle [at-that-track-speed]. A rule of thumb is 1 degree can change 150 rpms then at 80mph, the 42 degree angle should be substituted with a 41 degree angle.

Question; what should the “new” helix angles be?

Answer: 50/39…OR…some other fancy helix you can make, substituting a 41 degree at the problem track speed..

You can make any helix you want if you have the “data” and imagination on selecting “new” angles and duration (length) of them.

-First line shows the original 50/40 progressive.

-Second line shows a new 50/39 progressive

-Third line shows a progressive missing the 42 degree; the degrees go from 44, 43, 41, 40…etc

-Fourth line shows a progressive with a dual angle at the end (at the problem track speed)

-Fifth line shows a progressive with step “straight” angle…45, 44, 43, 41 at the problem track speed to full shift.

Question; Have you made helixes like this Joe? Answer: yes, many of each type you see there (over the years) but we’re missing one that i’ll explain further below “Dual progressive” later….

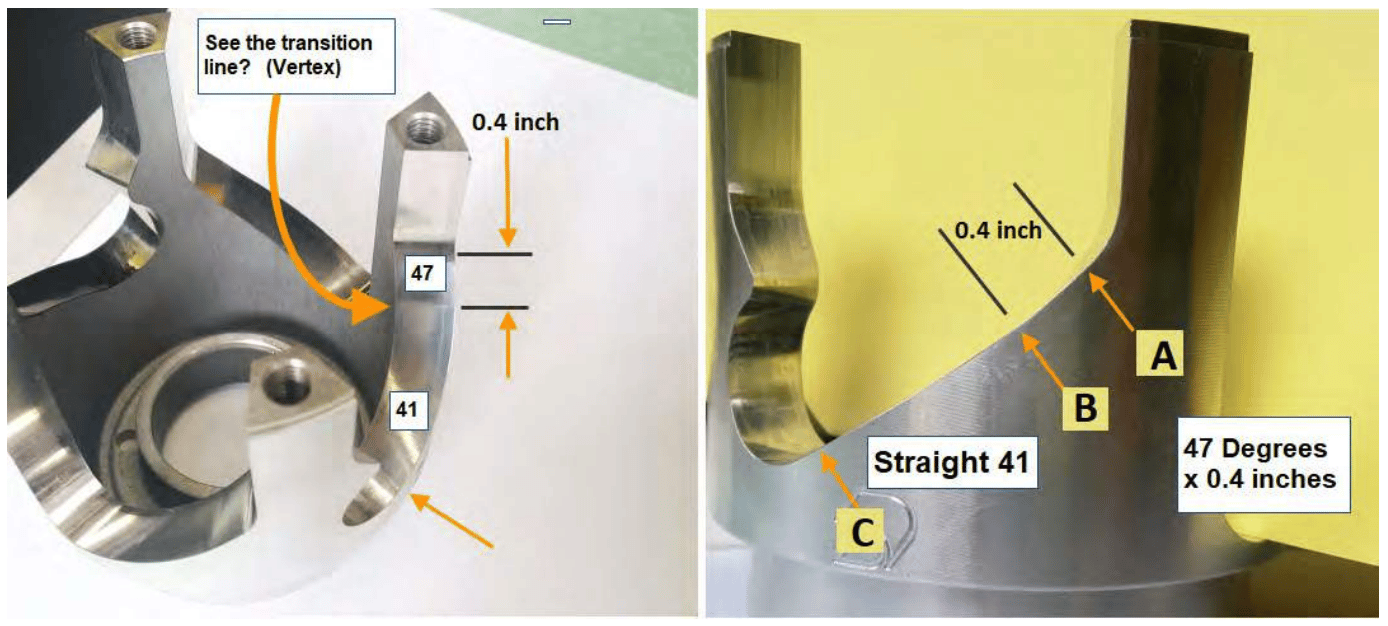

Step straight helix

Step straight is just that. Step of “X” degree for the “A to B” length (in inches) and transitions to “Y” degree for the “B to C” length for the rest of the helix angle. Its basically a dual angle helix with uneven lengths on the path.

IF sled geared for 100mph, THEN; 47 @ 0~31mph. (transition) 41 @ 31~100mph.

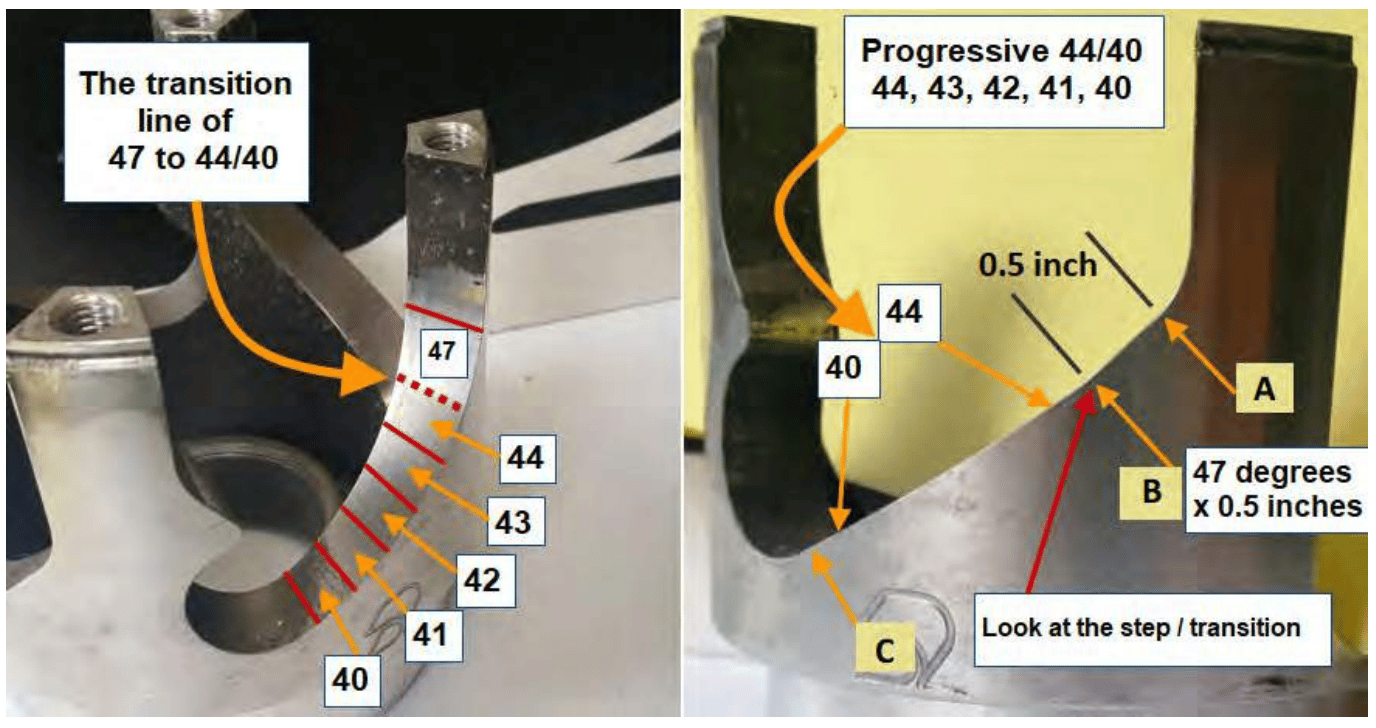

Step Progressive

Step progressive. Step of 47 degree from “A to B” length .5 inches and transitions into a progressive 44/40 (44, 43, 42, 41, 40).

IF sled geared for 100mph, THEN; 47 @ 0~34mph. (transition) 44 @ 34~47mph. 43 @ 47~60mph. 42 @ 60~73mph. 41 @ 73~87mph. 40 @ 87~100mph.

You can custom make a “step” any length you want if the helix programmer will do it for you. I’ve made step starts with lengths from 0.3 inch to 0.62 long. Like one sno-cross helix I did a 56 start for 3/8 inch step, transitioning to a progressive 45/38. I made a handful of helixes changing the length of the start from 1/4 inch to 1/2 inch and with the gearing and all the testing we did, the 3/8 inch step start worked best overall for holeshot.

A 53 start, the engine revved up too quick and track spun more.

A 58 start, the engine revved up ok but did not pull hard.

A 56 start give this particular engine the best rpm-acceleration from 5600 to 8600 rpms and won the holeshot.

The length of the 56 was determined by how smooth the track speed would accelerate without fluctuating engine rpms. The data recorder allowed us to figure out the best “rising rate” of engine speed to get to 8600 rpms and adjust the length of the 56 start.

Dual Progressive

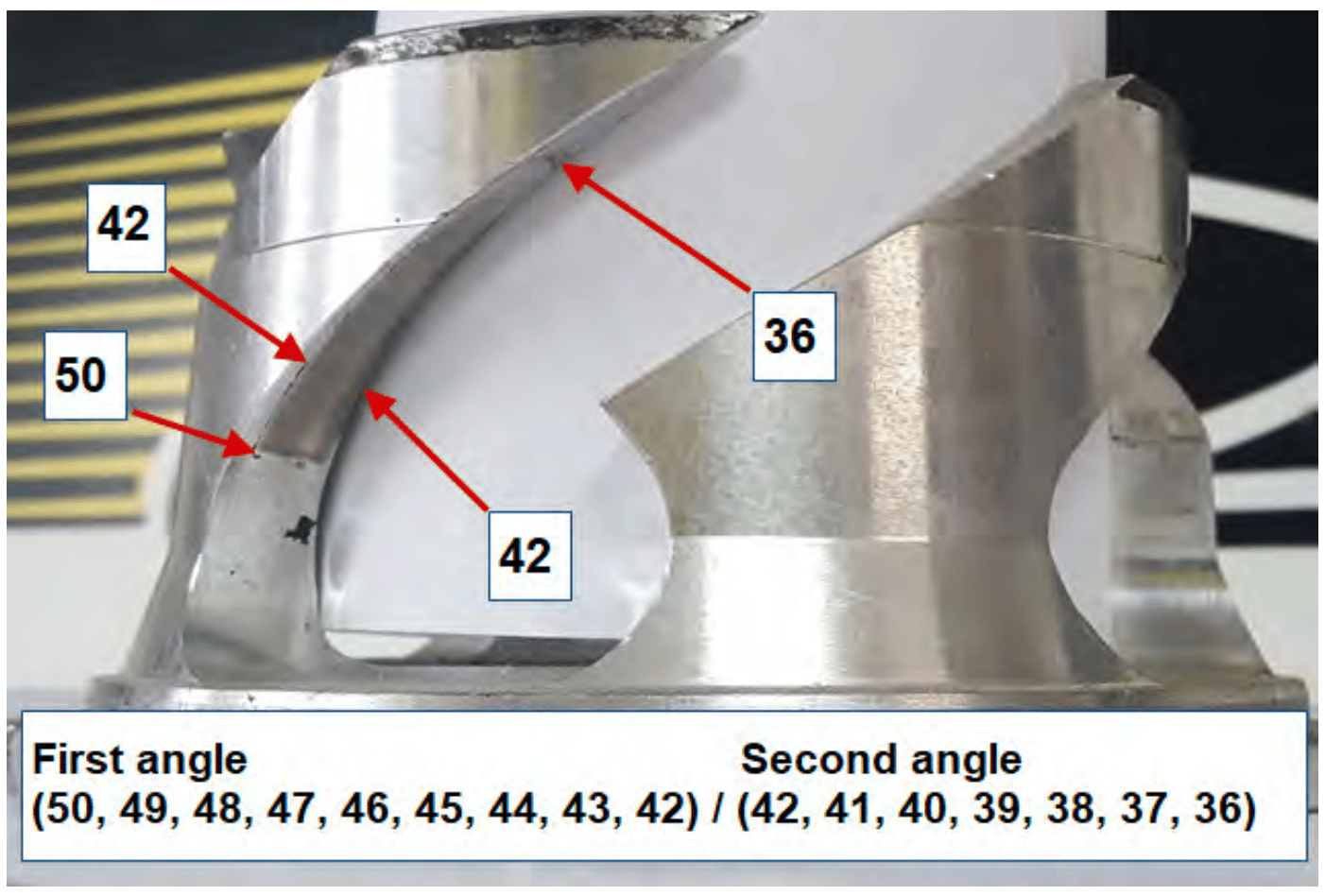

This dual progressive helix has 2 progressive helix angles in it. Jason K at team never made one before until I needed a helix made. (Winter 2014) The first set of numbers (step progressive) was too abrupt for the CAD program. I was trying to make a 47 step start, then transition to a 42/36 progressive. Jason called me up saying the programming did not like what I asked of it to make a that step helix. As we talked, we worked through a set of values for the CAD program to handle/process the transition from the first angle(step) to the second angle. The step ended up being a progressive angle becuase his CAD program would allow the transition. Ok, so-be-it, now Jason knows how to make a “Dual Progressive” helix and team-ind can make them, but there is none in their product guide; you have to request your own custom cut.

Track 1 is a (50/42)/(42/36)

Track 2 is a (46/42)/(42/36)

This worked good in oval track racing. Angles were good for holeshot and then when the sled running around 3/4 speed to full speed the roller used 38 to 36 degrees which give it really good top end with appropriate gearing.

When there is days with the track being soft, the owner was able to use a little lower engagement speed and combine track 2 to make the start softer and not spin-hookup and rpms drop. The sled could abruptly, but smootly holeshot on a softer, “mushy” ice track.

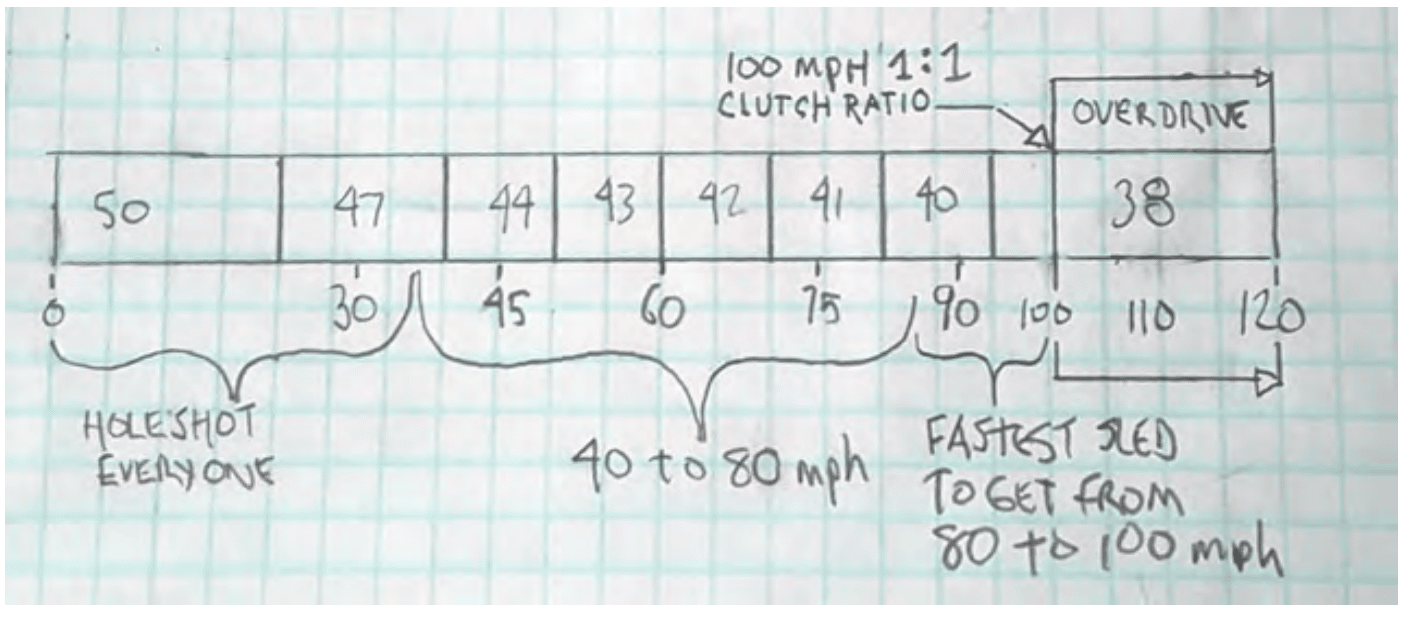

A funky helix (worked good)

Years ago I made some helixes for a guy cross-country racing a 600REV. The racetracks were 20 to 25 miles long. One driver at a time. Green-light-switch start, radio timed. Most of the racing is in winding trees, creeks, rivers. Speeds would briefly get to 80mph in different places with a straight stretch sprint of top speed near the finish line.

Here is the final helix for him.

The holeshot broken down to get the sled to speed up hardest to somewhere he had to let off the throttle; this 50/47 degree sped up harder than the stock 47/44.

Most of the races are 90% in the 35 to 80mph range, with needing strongest acceleration from 40 to 65mph; this is the 44~41 degree portion. The angles 44, 43, 42, 42 give the sled hard acceleration in that midrange and not lose rpms.

The last part of the race is a brief full throttle run to top end to cross the finish line. Most races, the fastest sleds crossing the finish line was between 85 to 95mph depending on CC class. The 440’s being slowest at 80mph, the 800’s being fastest at 95mph; the 40 degree angle got the sled to be at 85~90mph with a strong pull. If he was able to run a race where the top speed was between 95~100mph; the 38 degree gripped the belt good to achieve 100mph.

The sled geared, never going into overdrive, staying less than 1-1 clutch ratio giving maximum acceleration all the time.

Joe, the sled’s fast; I wish my skills were better to use what this 600’s got now. And then after marriage, had two kids and you know how that can kill a racing hobby. Haha.

Helix – Clutch ratios

Helix – Gearing affects position

Random helixes I have in my shop